The beginning of 2010 brought to the automotive scene rumor of an ongoing research within German manufacturer BMW's engineering labs, aimed at developing a split engine hybrid for the future generations of BMW models. Rumored to have already filed a patent application for the technology, BMW has opened our appetite for digging a bit deeper into the technology and finding out the whys and hows of a split cycle engine.

WHAT IS IT

As you might have guessed, a split engine is a type of internal combustion engine, but with a twist (or a split, if you like). To make the differences between the split engine and the regular one a bit easier to grasp, we will need to go into both of them at the same time and see what sets them apart.

In a conventional engine, each of the cylinders (regardless of the number of cylinders) is in charge with performing four tasks, one after the other: intake, compression, power, and exhaust (or, to explain it in a more graphic way, suck, squeeze, bang, blow). To do the four tasks, each cylinder requires two revolutions of the crankshaft.

The split engine one the other hand separates the four tasks into two groups. Say we have a four cylinder engine. The cylinders are grouped into two separate blocks, two cylinders/group, with each of the two groups being in charge with a different task: one group sucks and squeezes the gasoline, the other one bangs and blows it. The operating principle is simple: the compressed air needed is transferred from the compression cylinder to the power cylinder via a passage. After that, the fuel is injected into the cylinder and exploded.

In this engine, the cylinder at the left was the working cylinder, while the one at the right worked as a pump, combining gas and air. After compressing the mixture, the pump cylinder sent it through a large pipe connecting the two cylinders. It is then admitted to the working cylinder by a poppet valve.

Basically, the idea of a split engine slipped out of the public eye, despite several other attempts to build one throughout the 20th century.

All of them are based on the Scuderi Split-Cycle, a technology which according to Scuderi "solves both the breathing and thermal efficiency problems."

The engine has reduced clearance between the piston and the cylinder head (less than 1 mm), making mandatory the use of outwardly opening valves. The valves in turn enable the piston to move very close to the cylinder head and lead to the first advantage of such an engine: almost 100 percent of the compressed air is pushed from the compression cylinder into the crossover passage, killing any breathing problems.

Scuderi says that making the system work was rather a matter of determining how, not when to fire ATDC to get to the desired thermal efficiency.

Scuderi engineers managed to solve the problem by firing ATDC via a combination of high-pressure air in the transfer passage and high turbulence in the power cylinder. Because the compression cylinder is not limited by the combustion process in a split engine, it allows for a 75:1 compression ratio.

Firing ATDC allows the combustion process to start between 11 and 15 degrees after top dead center and end 23 degrees after ignition. This makes for a higher average combustion cylinder temperature but a lower peak temperature.

Simply put, it would be like having diesel torque meet gasoline speed and end up developing some 135 hp/liter at 6,000 rpm.

With the stricter emission and fuel consumption regulations which will come into effect starting this year in mind, Scuderi set out to envision a diesel version of the split cycle engine. The project is still in its infancy, but promises to offer up to 85 percent cuts in terms of NOx released into the air.

In a conventional engine, each of the cylinders (regardless of the number of cylinders) is in charge with performing four tasks, one after the other: intake, compression, power, and exhaust (or, to explain it in a more graphic way, suck, squeeze, bang, blow). To do the four tasks, each cylinder requires two revolutions of the crankshaft.

The split engine one the other hand separates the four tasks into two groups. Say we have a four cylinder engine. The cylinders are grouped into two separate blocks, two cylinders/group, with each of the two groups being in charge with a different task: one group sucks and squeezes the gasoline, the other one bangs and blows it. The operating principle is simple: the compressed air needed is transferred from the compression cylinder to the power cylinder via a passage. After that, the fuel is injected into the cylinder and exploded.

HISTORY

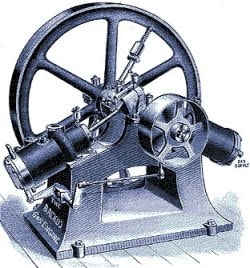

The first example of a split engine came way back in 1891, when the Backus Water Motor Company developed the so called Backus engine. The American Machinist Magazine described it back in 1891 as being a "modified A form, with the crank-shaft at the top, and there are two cylinders of equal size, which are inclined."In this engine, the cylinder at the left was the working cylinder, while the one at the right worked as a pump, combining gas and air. After compressing the mixture, the pump cylinder sent it through a large pipe connecting the two cylinders. It is then admitted to the working cylinder by a poppet valve.

Basically, the idea of a split engine slipped out of the public eye, despite several other attempts to build one throughout the 20th century.

SCUDERI SPLIT ENGINE

Massachusetts-based engineering company Scuderi Group may very well be the one which opens the stage for the split engine's future. Currently, Scuderi is looking to develop several types of such units, including an air-hybrid and a turbocharged version for gas powered engines, as well as a diesel version.All of them are based on the Scuderi Split-Cycle, a technology which according to Scuderi "solves both the breathing and thermal efficiency problems."

The engine has reduced clearance between the piston and the cylinder head (less than 1 mm), making mandatory the use of outwardly opening valves. The valves in turn enable the piston to move very close to the cylinder head and lead to the first advantage of such an engine: almost 100 percent of the compressed air is pushed from the compression cylinder into the crossover passage, killing any breathing problems.

ATDC

To solve the thermal efficiency problem, Scuderi had to think a bit outside the box. In a conventional engine, the spark ignites the fuel mixture before the piston reaches the farthest point to the crankshaft (a point called top dead center - TDC). For Scuderi, the ignition takes place after that the piston reaches that point (ATDC). Such a method is conventionally avoided in everyday combustion engines and has so far been used in the Nissan MA engine.Scuderi says that making the system work was rather a matter of determining how, not when to fire ATDC to get to the desired thermal efficiency.

Scuderi engineers managed to solve the problem by firing ATDC via a combination of high-pressure air in the transfer passage and high turbulence in the power cylinder. Because the compression cylinder is not limited by the combustion process in a split engine, it allows for a 75:1 compression ratio.

Firing ATDC allows the combustion process to start between 11 and 15 degrees after top dead center and end 23 degrees after ignition. This makes for a higher average combustion cylinder temperature but a lower peak temperature.

ADVANTAGES

The prototype in the works with Scuderi can operate at speeds of up to 6,000 rpm, while delivering about the same amount of horsepower as an engine with similar displacement and number of cylinders (four). Compared to a similar, but conventional engine, the Scuderi unit proves to deliver up to 80 percent less NOx levels. It is not clear how much gain will the engine bring in terms of fuel efficiency.TURBOCHARGED

Scuderi is working, as said, on several versions of the split cycle engine. The next logical step for the company was the creation of a turbocharged version of the unit, a version which, thanks to its ability to boost or turbocharge to more than 2.5 bar absolute pressure (a regular turbocharger only manages 1.5 bar absolute before pre-detonation occurs), allows for higher brake mean effective pressure (BMEP) and torque level.Simply put, it would be like having diesel torque meet gasoline speed and end up developing some 135 hp/liter at 6,000 rpm.

AIR-HYBRID AND DIESEL

Being basically an engine fitted with its very own compressor, the split-cycle engine would only require the addition of an air storage tank and a few buttons here and there to become a hybrid. If done properly, the unit would be able tap into and store the energy lost during its operation. Scuderi's wacky idea, if turned reality, would allow the driver to select an air-only driving mode. This means no electric motors and no batteries, the elements considered until now definitory for a hybrid.With the stricter emission and fuel consumption regulations which will come into effect starting this year in mind, Scuderi set out to envision a diesel version of the split cycle engine. The project is still in its infancy, but promises to offer up to 85 percent cuts in terms of NOx released into the air.