While Mazda may have used the Wankel rotary engine extensively in many of their cars, since back in 1967, when they launched their first rotary-powered offering, the Cosmo 110S, a lightweight sports car which managed to put out as much as 128 hp from a naturally-aspirated engine, displacing just 982cc. They used various rotary engines in many of their cars, before they finally put it out of production this year, along with the RX-8.

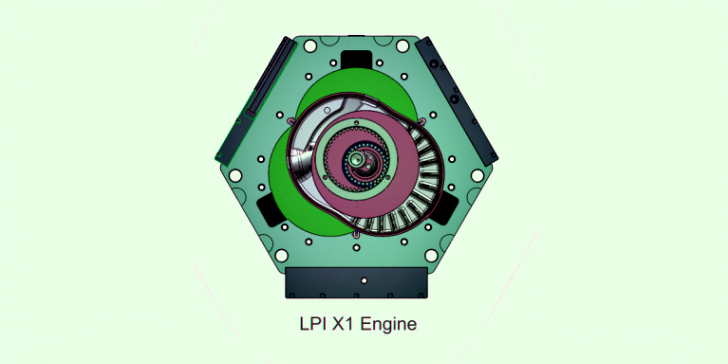

However, the rotary is far from dead, and Mazda is not the only interested party. A US company, LiquidPiston have taken the rotary engine concept, and with a few changes managed to achieve something truly amazing, and if they manage to get it into some sort of vehicle, this new motor will make pretty much any other internal combustion engine look and feel very outdated.

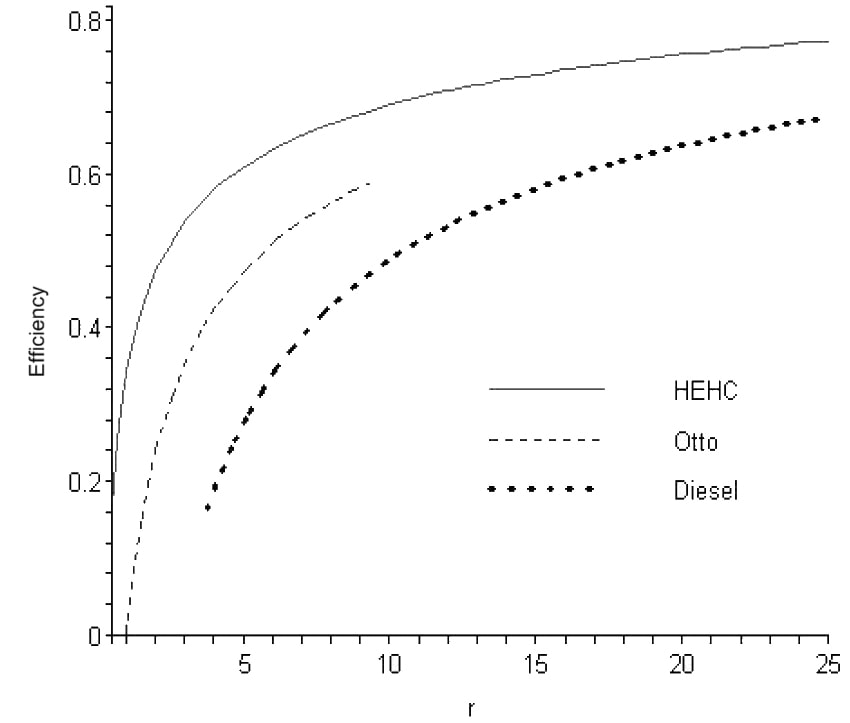

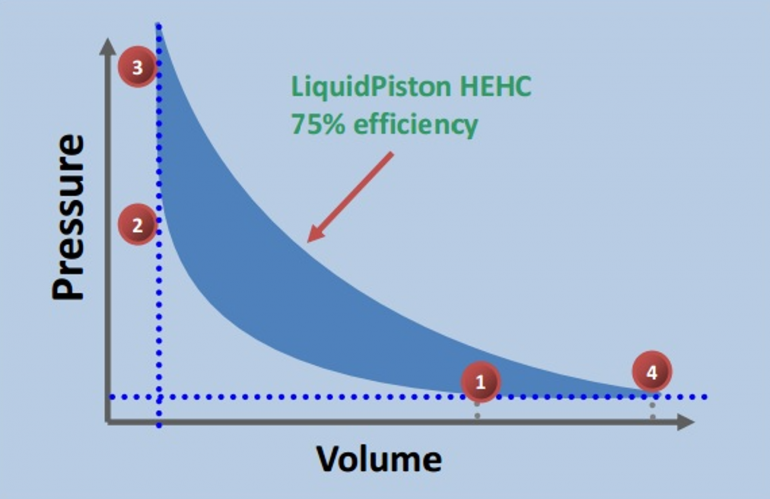

The engine in question is called the X2, and it shares some basic concepts with the Wankel, but the engineers behind it have taken it to a whole other level. They claim to have achieved a thermodynamic efficiency of 75%, from an engine which needs no cooling, no sound muffling and can run on a variety of fuels. Take into account that even the best of the modern diesels cannot achieve a thermodynamic efficiency of more than 50%, and this is a best-case scenario - petrol engines only manage about 30%.

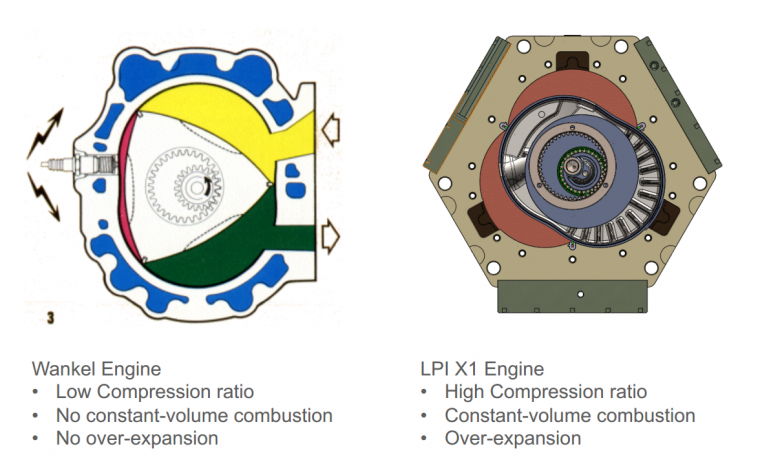

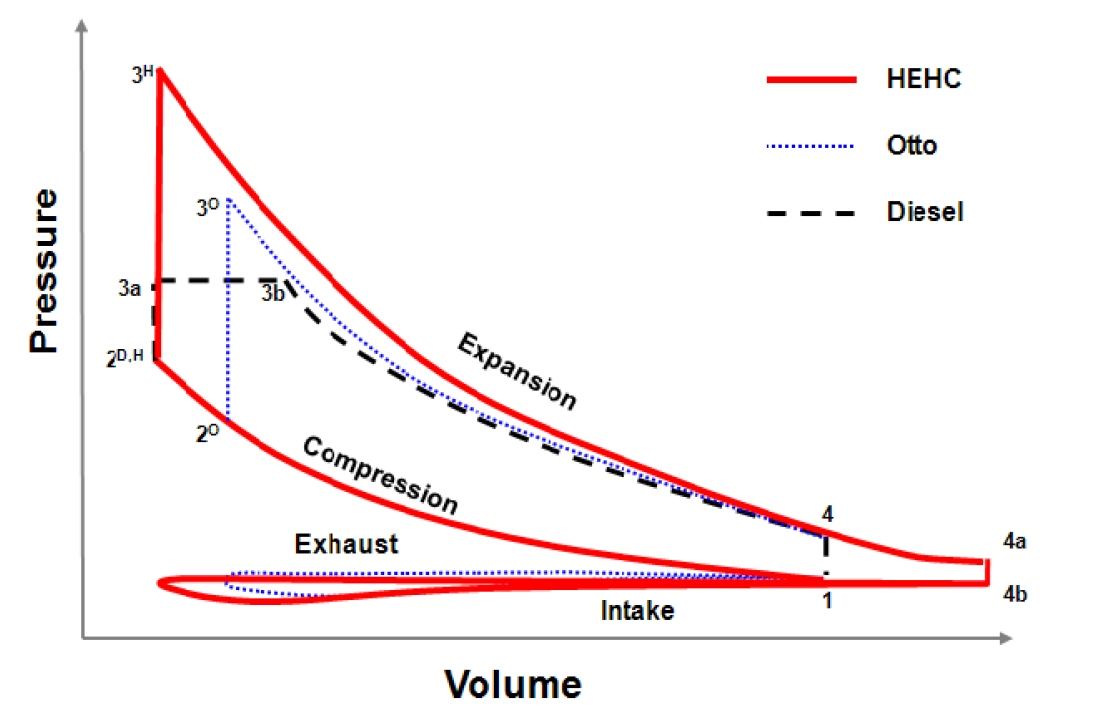

What LiquidPiston have done is not create a new engine, but rather a new type of engine, which runs on a cycle they have dubbed ‘High-Efficiency Hybrid Cycle’ (HEHC). It borrows elements from the conventional Otto, Diesel, Atkinson (which allows intake, compression, ignition and exhaust to occur in a single full rotation of the crank) and Rankine (which converts externally-supplied heat into work - it is used in more than 90% of the world’s electric energy production facilities) cycles and combines them in one compact, simple and very efficient package.

The idea is very clever, and if you think just how much heat is wasted through cooling an engine, which also requires additional energy to function and is therefor more wasteful, you begin to understand that instead of wasting the ‘excess heat’, it can be reconverted into energy, which is what LiquidPiston have done with the X2. Instead of cooling the engine, the heat is reused to boost efficiency.

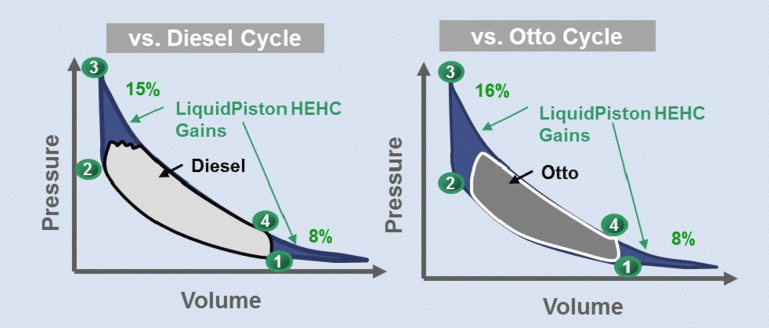

It also has a very high compression ratio, similar to a diesel engine, which is isolated in the combustion chamber, being kept at a constant pressure, and when fuel is injected it mixes with the compressed air and auto-ignites - again, just like a diesel. However, this is where it gets different. Instead of allowing the fuel/air mixture to expand, it is kept compressed, and therefor burns over a longer period of time - the Otto cycle.

Also, when the mixture is finally allowed to expand, it over-expands to near-atmospheric pressure, in order to completely burn all of the fuel, release its energy and then catch it as work. The manufacturer claims that this alone makes the engine quieter and more refined, as well as cleaner, therefor it does not really need complicated exhaust systems and catalytic converters, in order to clean and silence its exhaust.

Another positive aspect of its design is its simplicity, one of the reasons why the engineers chose a rotary design as a base to start from - it requires just 13 major parts, and it can be made to be much more compact than a conventional engine of similar power. It is also different to any other Wankel engine ever made, and it has been built in such a way that it doesn’t have many of the classic design’s drawbacks, like special seals, and lubrication, all of which have reportedly been done away-with.

The problem of apex seals was a major issue for any rotary-engined car, yet LiquidPiston say they have worked around the problem, by moving the seal from the actual rotor part, into the crancase, therefore not requiring any additional lubrication or special attention. If it proves reliable and successfully passes its testing phase, we could see derivatives of this engine/concept finding practical applications in a multitude of fields, especially the automotive one. However, while the company claims it is thermodynamically efficient, they do not mention if it is actually good on fuel, whatever that fuel may be - this remains to be seen.

From what we understand, such an engine would be perfect for running at constant RPMs, for prolonged periods of time, offering a constant supply of efficiently created and smooth power - again, if it is actually fuel-efficient. This means that it would be truly the perfect range extender engine for hybrids, like the Chevy Volt. With such an engine, burning some sort of non-petroleum fuel, which judging by what the company is saying about the X2, it can, perhaps a shift to full EVs won`t even be necessary, and batteries would be replaced by this simple and light powerplant, which would be perfectly suited for this application.

LiquidPiston is currently testing the X1, a previous version of this engine, if you will, but they say the X2 will become available for private testing next year, and once more money is injected into the company, they hope to have a working pre-production prototype of it working by 2014. Only time will tell if this is just another great idea thought up by a bunch of hopefuls, which will ultimately fail due to some sort of unforeseen technical glitch, lack of funding or, why not, a mysterious explosion which ravages the development facility, and all the ‘plans and blueprints’ for the engine will have been lost in the ensuing blaze.

If it proves as good as they say it is, it will be very rapidly adopted by the major automakers, and integrated into various green cars, as a range extender. If you don`t hear about this engine, or the concept behind it within the next few years, you will know they failed. We truly and genuinely hope they don’t and we hope to see and learn more about this unique concept in the coming years. If we don’t it will be one more reason to spend billions on the development of batteries and apparatuses to limit the amount of noxious gases coming out of ‘conventional’ internal combustion engines.

The engine in question is called the X2, and it shares some basic concepts with the Wankel, but the engineers behind it have taken it to a whole other level. They claim to have achieved a thermodynamic efficiency of 75%, from an engine which needs no cooling, no sound muffling and can run on a variety of fuels. Take into account that even the best of the modern diesels cannot achieve a thermodynamic efficiency of more than 50%, and this is a best-case scenario - petrol engines only manage about 30%.

What LiquidPiston have done is not create a new engine, but rather a new type of engine, which runs on a cycle they have dubbed ‘High-Efficiency Hybrid Cycle’ (HEHC). It borrows elements from the conventional Otto, Diesel, Atkinson (which allows intake, compression, ignition and exhaust to occur in a single full rotation of the crank) and Rankine (which converts externally-supplied heat into work - it is used in more than 90% of the world’s electric energy production facilities) cycles and combines them in one compact, simple and very efficient package.

The idea is very clever, and if you think just how much heat is wasted through cooling an engine, which also requires additional energy to function and is therefor more wasteful, you begin to understand that instead of wasting the ‘excess heat’, it can be reconverted into energy, which is what LiquidPiston have done with the X2. Instead of cooling the engine, the heat is reused to boost efficiency.

It also has a very high compression ratio, similar to a diesel engine, which is isolated in the combustion chamber, being kept at a constant pressure, and when fuel is injected it mixes with the compressed air and auto-ignites - again, just like a diesel. However, this is where it gets different. Instead of allowing the fuel/air mixture to expand, it is kept compressed, and therefor burns over a longer period of time - the Otto cycle.

Also, when the mixture is finally allowed to expand, it over-expands to near-atmospheric pressure, in order to completely burn all of the fuel, release its energy and then catch it as work. The manufacturer claims that this alone makes the engine quieter and more refined, as well as cleaner, therefor it does not really need complicated exhaust systems and catalytic converters, in order to clean and silence its exhaust.

Another positive aspect of its design is its simplicity, one of the reasons why the engineers chose a rotary design as a base to start from - it requires just 13 major parts, and it can be made to be much more compact than a conventional engine of similar power. It is also different to any other Wankel engine ever made, and it has been built in such a way that it doesn’t have many of the classic design’s drawbacks, like special seals, and lubrication, all of which have reportedly been done away-with.

The problem of apex seals was a major issue for any rotary-engined car, yet LiquidPiston say they have worked around the problem, by moving the seal from the actual rotor part, into the crancase, therefore not requiring any additional lubrication or special attention. If it proves reliable and successfully passes its testing phase, we could see derivatives of this engine/concept finding practical applications in a multitude of fields, especially the automotive one. However, while the company claims it is thermodynamically efficient, they do not mention if it is actually good on fuel, whatever that fuel may be - this remains to be seen.

From what we understand, such an engine would be perfect for running at constant RPMs, for prolonged periods of time, offering a constant supply of efficiently created and smooth power - again, if it is actually fuel-efficient. This means that it would be truly the perfect range extender engine for hybrids, like the Chevy Volt. With such an engine, burning some sort of non-petroleum fuel, which judging by what the company is saying about the X2, it can, perhaps a shift to full EVs won`t even be necessary, and batteries would be replaced by this simple and light powerplant, which would be perfectly suited for this application.

LiquidPiston is currently testing the X1, a previous version of this engine, if you will, but they say the X2 will become available for private testing next year, and once more money is injected into the company, they hope to have a working pre-production prototype of it working by 2014. Only time will tell if this is just another great idea thought up by a bunch of hopefuls, which will ultimately fail due to some sort of unforeseen technical glitch, lack of funding or, why not, a mysterious explosion which ravages the development facility, and all the ‘plans and blueprints’ for the engine will have been lost in the ensuing blaze.

If it proves as good as they say it is, it will be very rapidly adopted by the major automakers, and integrated into various green cars, as a range extender. If you don`t hear about this engine, or the concept behind it within the next few years, you will know they failed. We truly and genuinely hope they don’t and we hope to see and learn more about this unique concept in the coming years. If we don’t it will be one more reason to spend billions on the development of batteries and apparatuses to limit the amount of noxious gases coming out of ‘conventional’ internal combustion engines.