As much as we'd like to give Tesla the thumbs up for the Model 3, don’t forget that the electric sedan used to go through its brakes like a bull in a China shop. Also of interest is Elon Musk and his recurring calls to speed up production at the Fremont factory, but there’s a cost to that, a cost that Jason Fenske from Engineering Explained learned the hard way with his car.

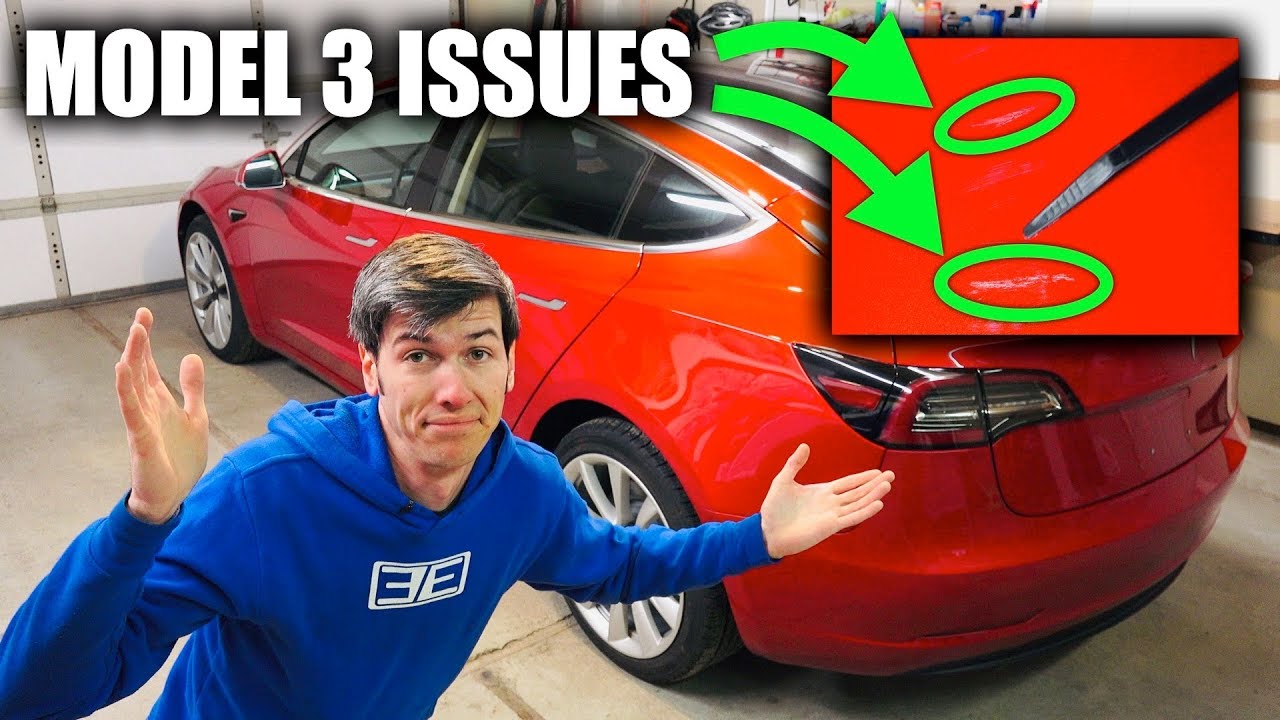

Delivered with 21.7 miles on the odometer, the vehicle’s delivery sheet doesn’t read anything in regard to noted damages. But on closer inspection, the list of problems starts with orange peel and numerous scratches on the doors and rear bumper. There’s even a speck of dust in the paintwork, which originates from Tesla’s paint shop.

Tesla offered Jason to fix these problems at no charge to the customer, but there’s more to this rear-wheel-drive Model 3 than meets the eye. More to the point, the panel gaps are atrocious even compared to the Subaru Crosstrek that Engineering Explained uses as his daily driver.

The inconsistencies are also present in terms of panel gaps of the glass roof, which goes to show how much of a compromise Tesla made by accelerating the production process of the Model 3 with countless robots. On the other hand, this production output (circa 1,000 3s per day) is necessary if the Palo Alto-based manufacturer wants to break even or make a profit.

Snazzy Labs commented on Jason’s video, claiming that even though he’s a Tesla fan and owner, these small but numerous issues are “completely unacceptable. Unacceptable in any new vehicle - especially one that has a $2,500 paint job."

On the other hand, Tesla’s quality control department has always been the consumer, starting with the Roadster and including the Model S and Model X. Another YouTube commenter who “worked on a Honda assembly line for a few years” added that “these scratches are absolutely unacceptable and should have been easily caught either by employees down line or by QA employees at the end of the line.”

If Tesla were to deliver a car with so many imperfections to you, how would you react?

Tesla offered Jason to fix these problems at no charge to the customer, but there’s more to this rear-wheel-drive Model 3 than meets the eye. More to the point, the panel gaps are atrocious even compared to the Subaru Crosstrek that Engineering Explained uses as his daily driver.

The inconsistencies are also present in terms of panel gaps of the glass roof, which goes to show how much of a compromise Tesla made by accelerating the production process of the Model 3 with countless robots. On the other hand, this production output (circa 1,000 3s per day) is necessary if the Palo Alto-based manufacturer wants to break even or make a profit.

Snazzy Labs commented on Jason’s video, claiming that even though he’s a Tesla fan and owner, these small but numerous issues are “completely unacceptable. Unacceptable in any new vehicle - especially one that has a $2,500 paint job."

On the other hand, Tesla’s quality control department has always been the consumer, starting with the Roadster and including the Model S and Model X. Another YouTube commenter who “worked on a Honda assembly line for a few years” added that “these scratches are absolutely unacceptable and should have been easily caught either by employees down line or by QA employees at the end of the line.”

If Tesla were to deliver a car with so many imperfections to you, how would you react?