QuantumScape’s latest news until now was that it had six automakers on its list of sampling agreements. That means overwhelming support and expectation from car companies about the technology it is developing for solid-state batteries. The cell startup now confirmed that its secret sauce is indeed the ceramic separator its batteries use. It even felt comfortable to share how it is produced: through tape casting.

This technique was developed in the 1940s and is currently used with multilayer ceramic capacitors (MLCCs). It consists of mixing a powder with a liquid binder to create a viscous liquid named slurry. The slurry is then coated in a long carrier surface to form what the industry calls tape, thinner than human hair.

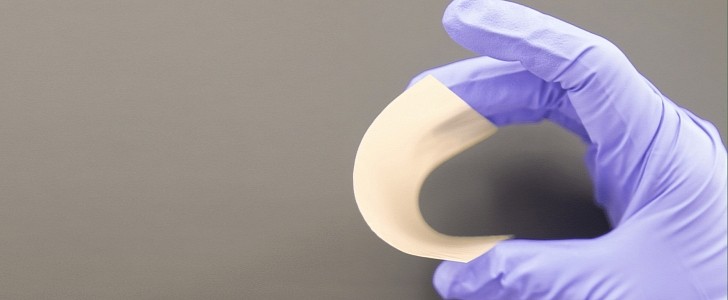

This tape format is what allows the ceramic material to be flexible. It reduces the “distance between the bending surface and the center of the material.” The longer this distance, the higher the probability that it will crack.

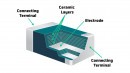

After the slurry forms this tape, it is dried and heated in a continuous-flow kiln. This gives QuantumScape a material that is Impervious to liquids, chemically and thermally stable, presents a crystal structure, high conductivity, and is flexible but resistant. It is through this material that lithium ions will travel to form the lithium metal anode in QuantumScape’s solid-state battery.

When the battery is manufactured, it only has lithium on the cathode side. The charging process makes the ions travel and gather on the other side of the ceramic separator. That’s how the lithium metal anode is formed.

QuantumScape already said that its solution is cathode-agnostic. In other words, it can work with LFP, NMC, NCA, or any other cathode material. Its ceramic separator resists the formation of dendrites with any of these chemistries. Unlike the plastic separators used by the industry, the ceramic stands very high temperatures without burning or deforming.

According to Niall Donnelly, having this thin and so effective separator is what allows the QuantumScape cell to present a higher energy density than other solutions. The battery startup vice president of research and development said It is more compact than any other lithium metal solution, which allows it to offer the same amount of energy in less space.

This tape format is what allows the ceramic material to be flexible. It reduces the “distance between the bending surface and the center of the material.” The longer this distance, the higher the probability that it will crack.

After the slurry forms this tape, it is dried and heated in a continuous-flow kiln. This gives QuantumScape a material that is Impervious to liquids, chemically and thermally stable, presents a crystal structure, high conductivity, and is flexible but resistant. It is through this material that lithium ions will travel to form the lithium metal anode in QuantumScape’s solid-state battery.

When the battery is manufactured, it only has lithium on the cathode side. The charging process makes the ions travel and gather on the other side of the ceramic separator. That’s how the lithium metal anode is formed.

QuantumScape already said that its solution is cathode-agnostic. In other words, it can work with LFP, NMC, NCA, or any other cathode material. Its ceramic separator resists the formation of dendrites with any of these chemistries. Unlike the plastic separators used by the industry, the ceramic stands very high temperatures without burning or deforming.

According to Niall Donnelly, having this thin and so effective separator is what allows the QuantumScape cell to present a higher energy density than other solutions. The battery startup vice president of research and development said It is more compact than any other lithium metal solution, which allows it to offer the same amount of energy in less space.