Sakuu has already shared a lot with us. We know its Sakuu-LM (Lithium Metal) cells offer 800 Wh/l, which equates to about 300 Wh/kg. They also present discharge rates of 3C and should be powering two-wheelers since the end of 2022, but that has not happened. That did not prevent the startup from choosing Porsche Consulting to design its future factories.

Sakuu believes the automaker’s subsidiary will help it “prioritize sustainable design while maximizing manufacturing efficiencies.” Porsche Consulting has extensive experience with large-scale factory designs. Predictably, that is more concentrated in the automotive industry.

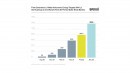

As familiar as Porsche Consulting is with giant plants, it will also have to know Sakuu’s Kavian platform intimately to come up with the best design for the startup’s factories. We have no idea how big each of these plants will be, but the startup said it wants to have an installed capacity of 200 GWh per year by 2030. If Sakuu follows the industry’s standard, it could have five factories with a capacity of 40 GWh each.

The Sakuu-LM pouch cells seem to be a sort of testbed for the Swift Print solid-state batteries and the additive manufacturing that intends to make them possible. In both cases, one crucial element must be the same: the proprietary non-flammable electrolyte the startup has developed. Not catching fire must not be the only thing that makes it unique.

Lithium metal cells have a higher energy density, but are not feasible for production because they are highly subject to dendrite formation. Dendrites are tiny lithium spikes that grow from the anode to the cathode. When they touch, a short circuit ensues, causing fires or explosions. Companies that promised to deliver lithium metal batteries that can reach production lines follow different strategies.

QuantumScape developed a ceramic separator that prevents dendrite formation between the lithium metal anode and the cathode. SES coats the lithium metal anode with a proprietary protecting polymer coating. We suppose Sakuu’s electrolyte plays a role in preventing dendrites, but we are not sure about it.

We also need to discover how the startup’s factories will be compared to the ones currently producing cells. 3D printing will make it a lot different in some aspects, but some others must be similar to the ones already in use nowadays. More than having a technological breakthrough, battery startups have to find ways to deliver them in high volume. This is what brings costs down.

By hiring Porsche Consulting, Sakuu seems to be pretty confident about what it developed. Either that or its investors have deep pockets and are betting high on what the battery startup promised. We should only learn about that when the company’s first factory is ready to deliver the goods. Hopefully, it will not take much longer.

As familiar as Porsche Consulting is with giant plants, it will also have to know Sakuu’s Kavian platform intimately to come up with the best design for the startup’s factories. We have no idea how big each of these plants will be, but the startup said it wants to have an installed capacity of 200 GWh per year by 2030. If Sakuu follows the industry’s standard, it could have five factories with a capacity of 40 GWh each.

The Sakuu-LM pouch cells seem to be a sort of testbed for the Swift Print solid-state batteries and the additive manufacturing that intends to make them possible. In both cases, one crucial element must be the same: the proprietary non-flammable electrolyte the startup has developed. Not catching fire must not be the only thing that makes it unique.

Lithium metal cells have a higher energy density, but are not feasible for production because they are highly subject to dendrite formation. Dendrites are tiny lithium spikes that grow from the anode to the cathode. When they touch, a short circuit ensues, causing fires or explosions. Companies that promised to deliver lithium metal batteries that can reach production lines follow different strategies.

QuantumScape developed a ceramic separator that prevents dendrite formation between the lithium metal anode and the cathode. SES coats the lithium metal anode with a proprietary protecting polymer coating. We suppose Sakuu’s electrolyte plays a role in preventing dendrites, but we are not sure about it.

We also need to discover how the startup’s factories will be compared to the ones currently producing cells. 3D printing will make it a lot different in some aspects, but some others must be similar to the ones already in use nowadays. More than having a technological breakthrough, battery startups have to find ways to deliver them in high volume. This is what brings costs down.

By hiring Porsche Consulting, Sakuu seems to be pretty confident about what it developed. Either that or its investors have deep pockets and are betting high on what the battery startup promised. We should only learn about that when the company’s first factory is ready to deliver the goods. Hopefully, it will not take much longer.