Using hydrogen for transportation is criticized by many. It would not be as energy-efficient as batteries, and a recent study even pointed out that producing it can be more pollutant than just burning the natural gas from where it is extracted. One of the main hurdles involving it is storage: putting the gas in a tank demands a lot of energy. E for Electric discovered a “solid-state hydrogen fueling” thanks to Sandy Munro and told us more about Plasma Kinetics, the company that developed it.

Alex Guberman interviewed Paul Smith, the company’s founder. When he introduced the technology in 2008, the U.S. government first called it “transformational,” then changed that to “disruptive.” Sadly, the government also slowed down the researches by restricting the company’s patents until 2017. Plasma Kinetics can now sell products based on them with restrictions.

Smith told Guberman his company is under ITAR (International Trade and Arms Regulations). That means his company cannot export this tech for missile fuel, which was never the focus of the “solid-state hydrogen fueling,” as Munro defined it.

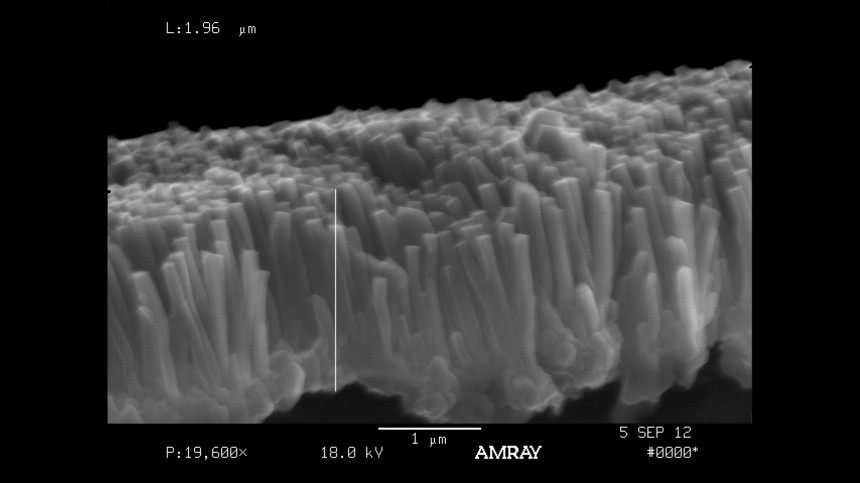

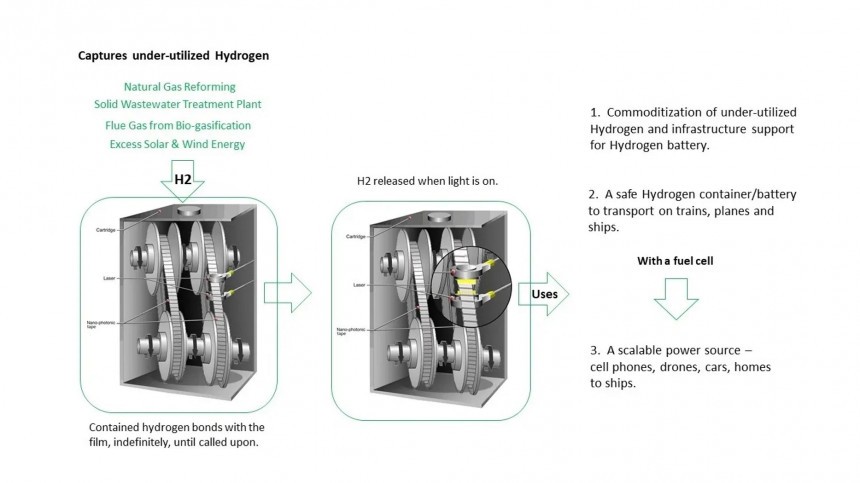

Smith has a background in computer chip manufacturing, and he approached the hydrogen storage issue with the same idea. In chips, engineers try to “layer up materials and get the conductivity the way you want it.” In Plasma Kinetics’ invention, they did the same to conduct light through a “whole bunch of negatively charged material.”

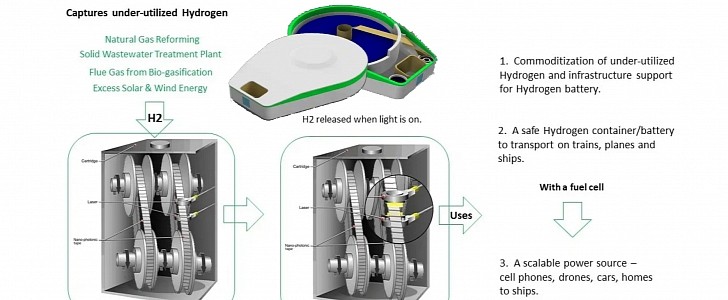

What happens is that his negatively charged material absorbs hydrogen. When light passes through it, the polarity of the bonds changes to positive, and the hydrogen is released. That’s a much better process than compressing hydrogen to 5,000 psi up to 10,000 psi, as today’s fuel cells need. For example, the Toyota Mirai holds 5.5 kg of hydrogen at that pressure.

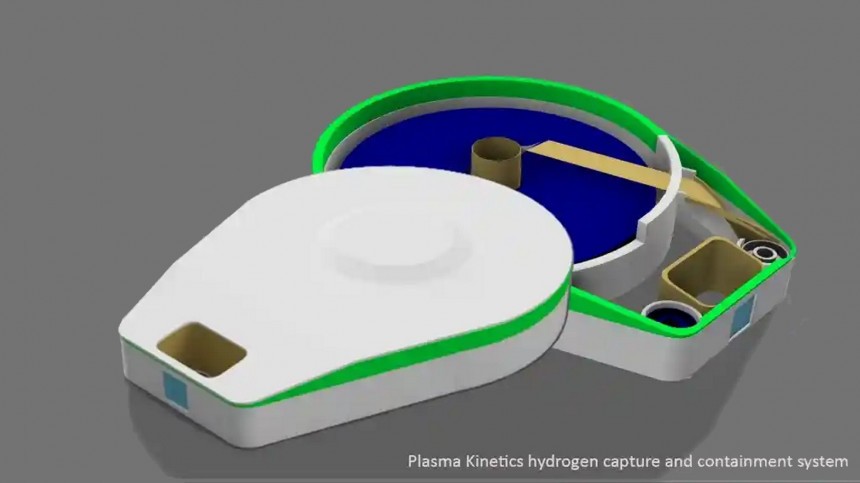

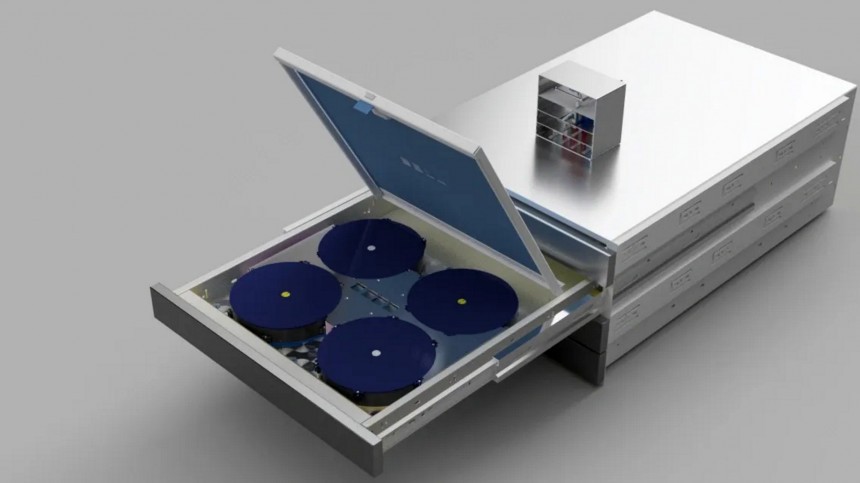

This material Plasma Kinetics developed can be used as a disc or as a film that is just one-tenth of a thickness of a human hair. At first, the discs helped the company to explain the technology: hydrogen would be released when the laser hit it as a compact disc would “release music” when the laser reader hit it. However, the nano graphite film proved to be a better means to deal with hydrogen storage.

One of the main advantages it presents is mass. The “cassette” with this hydrogen-filled film would offer the same amount of hydrogen a tank with hydrogen pressed at 5,000 psi would without the extra energy for compressing the gas. That would allow the Plasma Kinetics solution to store hydrogen generated by renewable energy sources such as solar or wind power plants.

Being more specific, Smith said that a 15-pound roll of this film could get an FCEV to drive 20 miles. Trucks get a 370-lb (168-kg) cylinder that offers 570 mi (917 km) of range. Even aircraft companies would be considering using it. The Plasma Kinetics founder said that his company’s solution weighs only one-third of batteries for the same amount of energy.

Plasma Kinetics would now be working on an automated system to get these rolls or cylinders out of cars and replace them with new ones. We can imagine something like the swappable batteries on Nio or even something less complex than that.

The leading edge of this tech is cost. It does not need the expensive carbon fiber tanks in which hydrogen is currently stored. According to Smith, the Plasma Kinetics technology already costs only 20% of what batteries demand.

The executive recognizes that there’s a drawback: not being able just to plug your car at home and charge it, as you may with an electric vehicle. You have to produce hydrogen, store it, and use it to produce electricity with a fuel cell. The silver lining is that both electrolyzers and fuel cells are getting better and cheaper. An electrolyzer manufacturer would now be offering 35 years of warranty on its equipment.

Smith told Guberman that both the disc and the film can be reused up to 150 times and are 100% recyclable. The material deteriorates due to the formation of deuterium, or heavy hydrogen. When the light shines in the material, it does not release deuterium, and the material gets “soaked” with it as time goes by.

In the recycling process, the deuterium can be recovered and sold as a commodity, which covers the recycling costs. In other words, the recipient in which the hydrogen is stored would not cost anything to customers, just like people who buy propane pay just for the gas, not the tanks.

Plasma Kinetics aims to distribute its hydrogen storage solution in an easier and less expensive way than $3 million hydrogen stations. Smith said that a 20-foot container worth $200,000 could offer enough cassettes or canisters to multiple vehicles, which would reduce the cost of hydrogen distribution dramatically.

The first manufacturing unit for Plasma Kinetics should be in Arizona, but the company has already received requests from all over the world, especially from Asia and Europe. At $100 million a pop, the company expects to establish facilities in multiple locations. If they feasibly find a way to incorporate the cylinders and cassettes in real cars, the expansion may be even more aggressive.

Smith told Guberman his company is under ITAR (International Trade and Arms Regulations). That means his company cannot export this tech for missile fuel, which was never the focus of the “solid-state hydrogen fueling,” as Munro defined it.

Smith has a background in computer chip manufacturing, and he approached the hydrogen storage issue with the same idea. In chips, engineers try to “layer up materials and get the conductivity the way you want it.” In Plasma Kinetics’ invention, they did the same to conduct light through a “whole bunch of negatively charged material.”

This material Plasma Kinetics developed can be used as a disc or as a film that is just one-tenth of a thickness of a human hair. At first, the discs helped the company to explain the technology: hydrogen would be released when the laser hit it as a compact disc would “release music” when the laser reader hit it. However, the nano graphite film proved to be a better means to deal with hydrogen storage.

One of the main advantages it presents is mass. The “cassette” with this hydrogen-filled film would offer the same amount of hydrogen a tank with hydrogen pressed at 5,000 psi would without the extra energy for compressing the gas. That would allow the Plasma Kinetics solution to store hydrogen generated by renewable energy sources such as solar or wind power plants.

Plasma Kinetics would now be working on an automated system to get these rolls or cylinders out of cars and replace them with new ones. We can imagine something like the swappable batteries on Nio or even something less complex than that.

The leading edge of this tech is cost. It does not need the expensive carbon fiber tanks in which hydrogen is currently stored. According to Smith, the Plasma Kinetics technology already costs only 20% of what batteries demand.

Smith told Guberman that both the disc and the film can be reused up to 150 times and are 100% recyclable. The material deteriorates due to the formation of deuterium, or heavy hydrogen. When the light shines in the material, it does not release deuterium, and the material gets “soaked” with it as time goes by.

In the recycling process, the deuterium can be recovered and sold as a commodity, which covers the recycling costs. In other words, the recipient in which the hydrogen is stored would not cost anything to customers, just like people who buy propane pay just for the gas, not the tanks.

The first manufacturing unit for Plasma Kinetics should be in Arizona, but the company has already received requests from all over the world, especially from Asia and Europe. At $100 million a pop, the company expects to establish facilities in multiple locations. If they feasibly find a way to incorporate the cylinders and cassettes in real cars, the expansion may be even more aggressive.