Ever heard of Green Diesel? Well, it is more than just biodiesel, as it involves more sustainability and a smaller CO2 footprint. The term comes from Austrian oil giant OMV, which has employed the name Co-Processing to describe the method of manufacture.

Now, many of you already know that some older-model diesel engines can operate with cooking oil instead of conventional fossil fuels. However, that does not work for modern vehicles that employ common rail injection and higher pressures and temperatures. In other words, do not even think of using a drop of used cooking oil instead of diesel in a modern compression-ignition engine.

There are three generations of biofuels. The first of them means conventional fuel blended with oil from plants like sunflower, rapeseed, soy, or others.

The second-generation biofuel involves replacing oil with plant waste and residue, like used cooking oil, wood waste, manure, straws, etc., which are then turned into fuel.

The third generation of biofuel is still in its research phase and consists of fuel from algae or other sources, which manages to clean an area or re-use waste that would normally interfere with human or animal life.

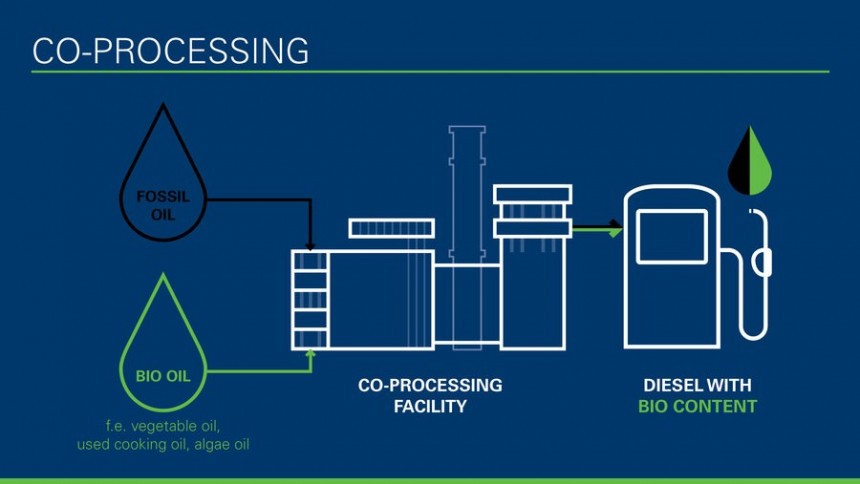

What the Austrians at OMV are doing at their Schwechat Refinery is something different. Instead of mixing already-finished diesel fuel with biofuel or just used cooking oil that has been filtered, the Co-Processing method takes things to a new level.

Their idea involves processing the biofuel along with the crude oil in a hydrotreatment plant. The latter involves adding hydrogen to the oil mixture to remove and impurities from the resulting fuel. Therefore, the product will be without oxygen, fat, or various other substances that are not meant to be in a combustion chamber.

The resulting product is a pure hydrocarbon, which is just like conventional diesel obtained from crude oil if it is analyzed from a chemical perspective. Unlike diesel blended with used cooking oil, this Green Diesel is a high-quality fuel that can work without a hitch in any car that requires this type of fuel.

According to OMV, the company has been experimenting with the matter since 2016 at its Schwechat Refinery, and now they want to build a new facility that will be capable of processing more bio-oil. Their next target involves 160,000 metric tons of biogenic feedstock, as the company calls the non-fossil oil it uses.

Another important achievement with the Co-Processing method is the possibility of using about any type of oil to mix with the crude. That means that the “traditional” rapeseed oil, already a big part of biodiesel, is not the only one to go to the refinery, like sunflower oil or even used cooking oil is also invited to the party.

With all that in mind, it is worth considering the quality of the supplied oil can be an issue, and the same can be said about availability. In other words, it is difficult for the company to source such a large quantity of used cooking oil or rapeseed oil for that matter. Obtaining the oil must not be the end goal, as the company must do it sustainably, which will not affect other crops or industries.

Moreover, if the oil they receive contains too much phosphorous, excessive sulfur, or other chemicals, it needs to be treated to ensure it will comply with all applicable norms. Mind you, it needs to be able to work in any diesel-engined vehicle sold across the world without risking any damage to it.

The Austrian company has also announced it will extract oil from cashew shells and even algae. The latter has been previously discussed as a fuel source before, and the goal is to figure out a sustainable source of oil that can yield reliable results with minimal processing.

That is not an easy task, but the next step for the Schwechat Refinery will come in 2023 when it will make hydrotreated vegetable oil. The latter is claimed to save up to 360,000 metric tons of CO2 each year when compared to plain old fossil fuel.

To put things into perspective, 360,000 metric tons of CO2 a year equates to the emissions of an average car driving around the Equator 60,000 times. That is a lot of miles, right? The said type of biofuel is meant to provide at least a 65 percent reduction of CO2 when compared to fossil diesel.

There are three generations of biofuels. The first of them means conventional fuel blended with oil from plants like sunflower, rapeseed, soy, or others.

The second-generation biofuel involves replacing oil with plant waste and residue, like used cooking oil, wood waste, manure, straws, etc., which are then turned into fuel.

The third generation of biofuel is still in its research phase and consists of fuel from algae or other sources, which manages to clean an area or re-use waste that would normally interfere with human or animal life.

What the Austrians at OMV are doing at their Schwechat Refinery is something different. Instead of mixing already-finished diesel fuel with biofuel or just used cooking oil that has been filtered, the Co-Processing method takes things to a new level.

Their idea involves processing the biofuel along with the crude oil in a hydrotreatment plant. The latter involves adding hydrogen to the oil mixture to remove and impurities from the resulting fuel. Therefore, the product will be without oxygen, fat, or various other substances that are not meant to be in a combustion chamber.

Why is this a big deal?

Well, conventional biodiesel can only use up to seven percent of biofuels. This is a restriction that is linked to quality, OMV explained. The industry standard mandates that, so there is no chance of it changing overnight. Meanwhile, the new Green Diesel that is made through Co-Processing allows for up to 25 percent bio-component mixed into this type of fuel.That is an eighteen percent increase in the amount of non-fossil fuel content in diesel, which is a dramatic improvement. This brings a significant reduction in carbon footprint and finds a new use for used oil that could have affected water supplies if it were not properly disposed of and reused.

According to OMV, the company has been experimenting with the matter since 2016 at its Schwechat Refinery, and now they want to build a new facility that will be capable of processing more bio-oil. Their next target involves 160,000 metric tons of biogenic feedstock, as the company calls the non-fossil oil it uses.

Another important achievement with the Co-Processing method is the possibility of using about any type of oil to mix with the crude. That means that the “traditional” rapeseed oil, already a big part of biodiesel, is not the only one to go to the refinery, like sunflower oil or even used cooking oil is also invited to the party.

With all that in mind, it is worth considering the quality of the supplied oil can be an issue, and the same can be said about availability. In other words, it is difficult for the company to source such a large quantity of used cooking oil or rapeseed oil for that matter. Obtaining the oil must not be the end goal, as the company must do it sustainably, which will not affect other crops or industries.

The Austrian company has also announced it will extract oil from cashew shells and even algae. The latter has been previously discussed as a fuel source before, and the goal is to figure out a sustainable source of oil that can yield reliable results with minimal processing.

That is not an easy task, but the next step for the Schwechat Refinery will come in 2023 when it will make hydrotreated vegetable oil. The latter is claimed to save up to 360,000 metric tons of CO2 each year when compared to plain old fossil fuel.

To put things into perspective, 360,000 metric tons of CO2 a year equates to the emissions of an average car driving around the Equator 60,000 times. That is a lot of miles, right? The said type of biofuel is meant to provide at least a 65 percent reduction of CO2 when compared to fossil diesel.