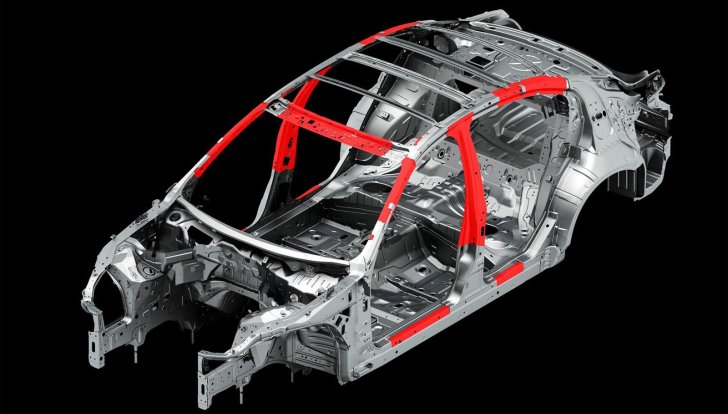

Nissan has announced it will expand the use of advanced high tensile steel, including the use of 1.2 gigapascal Ultra High Tensile Strength Steel with High Formability, in production models starting in 2017.

This hardened material will help reduce the weight of the vehicle by 15% and also promises to have safety benefits in case of crashes. The material will be used on up to o 25 percent of the vehicle parts (measured by weight) installed in its new production models in four years’ time.

But you won’t have to wait that long, since the 1.2 GPa will see its application in the new Infiniti Q50 luxury sedan that will enter production later this year.

Nissan says it’s the first company to combine Ultra High Tensile Strength Steel with High Formability, which means it can be used for much more complex shapes.

Making the vehicles lighter means less fuel can be because less power is required to move them. The company is aiming for a 35 percent improvement in fuel economy compared with 2005 on a corporate average for all Nissan vehicles by the end of fiscal 2016.

But you won’t have to wait that long, since the 1.2 GPa will see its application in the new Infiniti Q50 luxury sedan that will enter production later this year.

Nissan says it’s the first company to combine Ultra High Tensile Strength Steel with High Formability, which means it can be used for much more complex shapes.

Making the vehicles lighter means less fuel can be because less power is required to move them. The company is aiming for a 35 percent improvement in fuel economy compared with 2005 on a corporate average for all Nissan vehicles by the end of fiscal 2016.