The race to find better, more fuel-efficient ways of moving about the planet is most visible in the automotive industry, but other sectors of transportation are rapidly catching up. Especially the aviation industry, where everyone seems to be running toward more fuel-efficient engines.

One of the most ambitious such projects is run by NASA. It's called HyTEC, and first came to light in 2021. It's not necessarily a project meant to come up with a production engine per se, but with the technologies that could help a new jet engine use less fuel and release less harmful gasses.

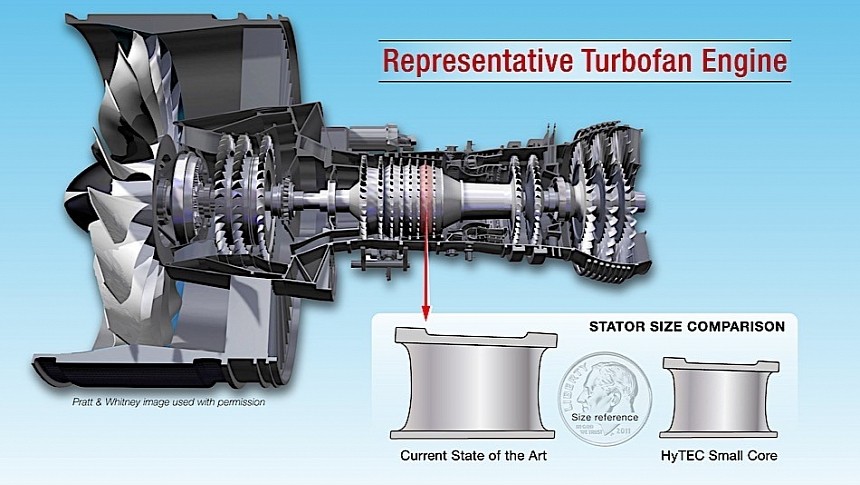

What NASA is researching is, in essence, a smaller core for a turbofan engine. It's supposed to keep the thrust levels we're used to and look pretty much the same as today's jet engines, but cut fuel consumption by at least ten percent.

Making an engine core smaller while keeping the same power levels does come with a series of challenges though. The most important has to do with the materials that'll be used to actually make the core, because smaller also means hotter. The current materials, obviously, will not work, so the HyTEC team has been very busy this past year testing all sorts of composites.

When NASA first dreamed up HyTEC, it planned on making the tech vailable for commercial applications in single-aisle aircraft as soon as the next decade. The materials issue was one of the biggest hurdles, but this week the space agency said engineers are almost done with that, moving the project closer to a demonstration soon.

We're told the list of potential materials has been narrowed down to a family called ceramic matrix composites (CMC). They will be used to build the engine core's components (compressor, combustion chamber, turbine, and exhaust nozzle), and they will then be covered in something called an environmental barrier coating (EBC).

"We've narrowed down the best materials so when we get to our full-on demonstrations, one clear winner can more efficiently be identified," Anthony Nerone, HyTEC head said in a statement. "The CMCs and EBCs that look promising now graduate to the next round. It's a sort of screening process."

As for how the HyTEC will actually work, it all boils down to how much more air it uses for thrust than for combustion. It's something called bypass ratio, and this design should allow for 15 times more air being used for thurst. For reference, the Boeing 787 Dreamliner is the plane with one of the best bypass ratios, at a respectable 9.

At the time of writing the HyTEC project includes not only NASA, but also engine maker Pratt & Whitney. Engineers expect more advanced tests on materials and components to begin just a few years from now.

What NASA is researching is, in essence, a smaller core for a turbofan engine. It's supposed to keep the thrust levels we're used to and look pretty much the same as today's jet engines, but cut fuel consumption by at least ten percent.

Making an engine core smaller while keeping the same power levels does come with a series of challenges though. The most important has to do with the materials that'll be used to actually make the core, because smaller also means hotter. The current materials, obviously, will not work, so the HyTEC team has been very busy this past year testing all sorts of composites.

When NASA first dreamed up HyTEC, it planned on making the tech vailable for commercial applications in single-aisle aircraft as soon as the next decade. The materials issue was one of the biggest hurdles, but this week the space agency said engineers are almost done with that, moving the project closer to a demonstration soon.

We're told the list of potential materials has been narrowed down to a family called ceramic matrix composites (CMC). They will be used to build the engine core's components (compressor, combustion chamber, turbine, and exhaust nozzle), and they will then be covered in something called an environmental barrier coating (EBC).

"We've narrowed down the best materials so when we get to our full-on demonstrations, one clear winner can more efficiently be identified," Anthony Nerone, HyTEC head said in a statement. "The CMCs and EBCs that look promising now graduate to the next round. It's a sort of screening process."

As for how the HyTEC will actually work, it all boils down to how much more air it uses for thrust than for combustion. It's something called bypass ratio, and this design should allow for 15 times more air being used for thurst. For reference, the Boeing 787 Dreamliner is the plane with one of the best bypass ratios, at a respectable 9.

At the time of writing the HyTEC project includes not only NASA, but also engine maker Pratt & Whitney. Engineers expect more advanced tests on materials and components to begin just a few years from now.