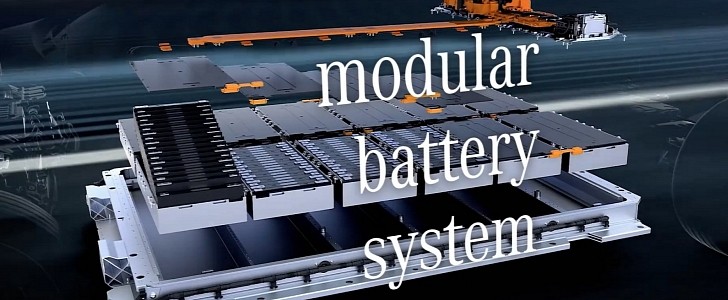

When Mercedes-Benz presented its strategy to become electric-only “where market conditions allow," it also revealed something interesting about what it plans for future cells. According to the company, it is “aiming for a modular battery system that consists of uniformly designed components and a standardized interface to the entire vehicle.” Yes, you have heard it before from Volkswagen under the name “unified cell.”

Even the images Mercedes-Benz unveiled at its strategy presentation confirm the resemblances. The cells for the “modular battery system” are prismatic and very similar to those presented by Volkswagen. One of the differences is that Mercedes-Benz presented them in modules: Volkswagen plans to use them in the CTP (cell-to-pack) configuration.

According to Markus Schäfer, Mercedes-Benz COO (Chief Operating Officer), “only two differentiating characteristics will create the necessary variance in terms of range, charging and driving performance: cell chemistry and the height.” In that sense, the German brand will do things in a slightly different manner than Volkswagen.

When it disclosed its electrification strategy, Volkswagen announced it would use the same prismatic cell cases for the unified cells. Only chemistry would make them differ from each other. Mercedes-Benz seems to think it is better for them to have variable heights to pack more or less energy, depending on their applications.

That is possibly what will allow “more than 90% of all future Mercedes vehicles” to “be based on a common battery platform,” according to Schäfer. Volkswagen will have 80% of its vehicles using the unified cell.

Unlike Volkswagen, Mercedes-Benz did not disclose all chemistries with which it is willing to work. Sajjad Khan, its Chief Technical Officer, only mentioned that the EQS currently uses NMC811 cells and that his teams are working to increase the energy density in them. The plan is to adopt silicon-carbon composite in the anode made by SilaNano to reach 900 Wh/l. Mercedes-Benz would also be investigating solid-state cells to get “ up to 1,200 Wh/l and more than 400 Wh/kg.”

Harald Wilhelm, the board member responsible for Finance & Controlling and Daimler Mobility, said that LFP batteries would help bring the cost per kWh below €100. Although it does not mean the company is planning to use them, it would not make sense for him to mention that if that was not the case.

Schäfer said that these cells would be produced in eight factories for a capacity of 200 GWh. With that production capacity, he believes the company will secure supply for all the electric cars it plans to produce. The company also disclosed that it wants to have a battery recycling plant in Kuppenheim, Germany, operating by 2023.

According to the executive, four of these factories would be located in Europe and one in the U.S. In his presentation, we could see a map with the locations. Unless Mercedes-Benz made similar mistakes to those we spotted on a Volkswagen chart, something does not match.

The map first shows battery factory icons in Germany, Italy, Turkey, and somewhere in the north of Africa (Mali or Algeria, apparently). When the map moves to the East, it presents these icons in Russia, India, China (or Vietnam, but China is more likely), and Australia. The U.S. factory confirmed by Schäfer does not show up on the map.

Count them all, and you will get to nine locations (the eight in the map and the American plant), but only three are in Europe. With one of them in the Sahara desert and another one in Australia, it seems that Mercedes-Benz is trying to have some factories close to critical lithium supplies even in countries with no automotive industry. We’ll ask Mercedes-Benz about that.

What we can tell for sure is that Mercedes-Benz will put the chemistries it plans to use in “a modular battery system” with “uniformly designed components and a standardized interface.” Scale is still the name of the game for German carmakers, even if they have marginally different approaches to get there.

According to Markus Schäfer, Mercedes-Benz COO (Chief Operating Officer), “only two differentiating characteristics will create the necessary variance in terms of range, charging and driving performance: cell chemistry and the height.” In that sense, the German brand will do things in a slightly different manner than Volkswagen.

When it disclosed its electrification strategy, Volkswagen announced it would use the same prismatic cell cases for the unified cells. Only chemistry would make them differ from each other. Mercedes-Benz seems to think it is better for them to have variable heights to pack more or less energy, depending on their applications.

Unlike Volkswagen, Mercedes-Benz did not disclose all chemistries with which it is willing to work. Sajjad Khan, its Chief Technical Officer, only mentioned that the EQS currently uses NMC811 cells and that his teams are working to increase the energy density in them. The plan is to adopt silicon-carbon composite in the anode made by SilaNano to reach 900 Wh/l. Mercedes-Benz would also be investigating solid-state cells to get “ up to 1,200 Wh/l and more than 400 Wh/kg.”

Harald Wilhelm, the board member responsible for Finance & Controlling and Daimler Mobility, said that LFP batteries would help bring the cost per kWh below €100. Although it does not mean the company is planning to use them, it would not make sense for him to mention that if that was not the case.

According to the executive, four of these factories would be located in Europe and one in the U.S. In his presentation, we could see a map with the locations. Unless Mercedes-Benz made similar mistakes to those we spotted on a Volkswagen chart, something does not match.

The map first shows battery factory icons in Germany, Italy, Turkey, and somewhere in the north of Africa (Mali or Algeria, apparently). When the map moves to the East, it presents these icons in Russia, India, China (or Vietnam, but China is more likely), and Australia. The U.S. factory confirmed by Schäfer does not show up on the map.

What we can tell for sure is that Mercedes-Benz will put the chemistries it plans to use in “a modular battery system” with “uniformly designed components and a standardized interface.” Scale is still the name of the game for German carmakers, even if they have marginally different approaches to get there.