Most people following news about the Mercedes-Benz VISION EQXX focused on its appearance. Some even believe that the front three-pointed star badge is more to the left than it should be. None of that really matters to what this EV stands for: energy efficiency. However, Mercedes-Benz achieved that in unusual (and controversial) ways.

The three pillars for traveling with the least energy demand involve mass reduction, aerodynamics perfecting, and powertrain efficiency improvement. Mercedes-Benz said in the presentation video that the VISION EQXX had a drag coefficient of only 0.17. That’s amazing, but the company did not seem to give it as much importance as it gave to reducing weight.

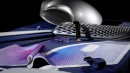

The VISION EQXX has unique elements, such as GFRP (glass-fiber-reinforced plastic) springs developed with Rheinmetall Automotive. You can see right below that the material they use is not the only surprise they reserve: their format is also pretty uncommon. Mercedes-Benz only mentioned that they are lighter than conventional coil springs but did not refer to their durability.

This text was pretty much ready when Green Car Reports revealed the most controversial aspect of weight reduction in the VISION EQXX: an air-cooled battery pack. Curiously, Mercedes-Benz avoids calling it by what it is as much as possible. It says that the car presents “fully passive cooling,” a cooling plate, water pumps, and a cooling fan, but you have to ask the company how they work to get the whole picture. That’s what we did.

To GCR, Markus Schäfer said that pumping liquids around would demand precious energy for the VISION EQXX to travel further. Daimler’s CTO (chief technology officer) thinks there is no need for liquid cooling thanks to how efficient the electric drivetrain is. Mercedes-Benz includes everything involved with moving the EV – from the battery pack to the wheels – under this classification.

This set of elements would deliver a 95% efficiency. That means that 95% of the electricity used to power the car is converted into movement. This number shows impressive advancements in perfecting the powertrain. It is unclear if working at more than 900V helped the company achieve this result. Unfortunately, Mercedes-Benz did not disclose which measures it took to get there.

The point is that the company’s excuse for going with an air-cooled battery pack was that it had only 5% of waste. Heat comes from that wasted energy – that’s how losses manifest. However, Mercedes-Benz did not mention that there are wastes in the charging process as well – especially when it is fast. And these losses generate a lot of heat.

For the automaker, a simple cooling plate underneath the battery pack is enough for bringing down the battery pack temperature. The cooling plate does not use any sort of liquid circulation: it is just a metal heat exchange surface. When the car is in hot weather, climbing a steep slope, or stuck in traffic, a cooling fan would kick in but only for the electric drive unit, not for the battery pack.

Although the 150 kW motor makes the VISION EQXX have a relatively low discharge demand rate (1.5 C), this EV would probably need to fast charge every once in a while if it reached mass production. Mercedes-Benz said it could add 300 km (186 mi) of range in 15 minutes. That confirms the battery pack would heat up quite a bit in such situations, immediately reducing charging speed. An insufficiently cooled battery pack would also lose capacity and present reliability issues in the long term.

In short, either Mercedes-Benz found a way to deal with fast-charging effects and did not tell us about that, or it just omitted the problem to solve it if it ever adopts this air-cooled battery pack in production cars. The VISION EQXX suggests that this will be the case.

By deciding to save weight and energy by killing liquid-cooling in this smaller-than-100-kWh battery pack, the automaker prevented any comparison with modern battery packs. All of them are liquid-cooled. The one in the current LEAF was conceived more than ten years ago, and even Nissan gave up on the idea.

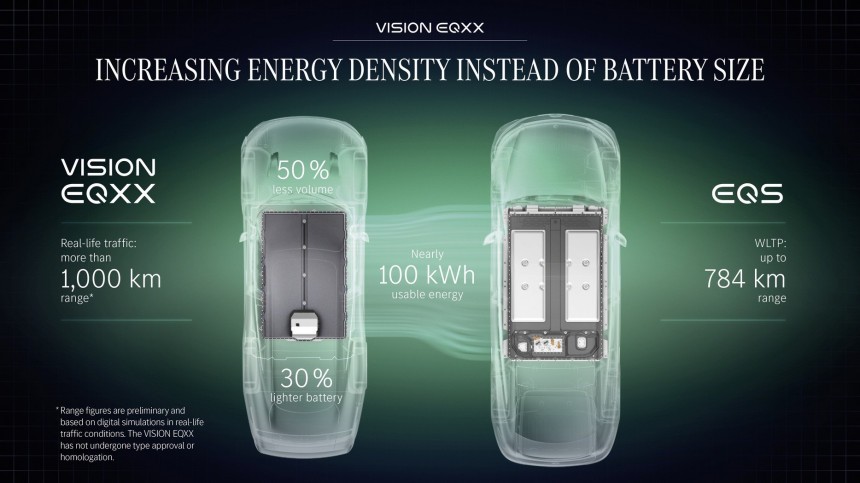

If the VISION EQXX’s battery pack was liquid-cooled, we could compare it to similar components to understand the impact that higher silicon content in the anodes made. Mercedes-Benz also said that the separate compartment for electronic components – called OneBox – saved space from squeezing more cells into the battery pack.

Those measures would have helped the automaker reach 400 Wh/l, reduce the battery pack volume by 50%, and the weight by 30%, at 495 kg (1,091 lb). The issue is that most of the volume reduction and weight savings must have come from eliminating liquid cooling. Ironically, the lack of coolant diluted the gains the other solutions offered.

Mercedes-Benz’s proposal for the battery pack gets even more questionable after what ONE (Our Next Energy) recently revealed. The battery tech startup disclosed that it developed a battery pack called Gemini 001. After fitting one into a Model S, the EV managed to run 752 mi (1,210.2 km) on a single charge. With liquid cooling, it presents 416-Wh/l and 203.7 kWh, double the energy capacity on the VISION EQXX.

We get it that the new Mercedes-Benz is allegedly just a concept car. In other words, its only mission would be to prove that it is possible to run 1,000 km with a 100 kWh battery pack. However, it seems to be more than that. If the goal was to make something that would never reach assembly lines, why didn’t Mercedes-Benz go with cameras instead of rear-view mirrors? The Honda e adopts cameras because they help it save energy – and it is a production car.

Another controversial aspect of Mercedes-Benz is the adoption of aluminum brake disks. On paper, it looks like a stroke of genius. Apart from being lighter, they are also corrosion-free. That can be really helpful in electric cars because EVs do not use brakes as much as conventional cars due to regenerative braking. Another advantage these brake disks would offer is to reduce brake dust emission by up to 90%.

Here, the problem is that nobody uses aluminum disk brakes for a reason: aluminum expands a lot more than iron when it is exposed to heat. Mercedes-Benz did not reveal who makes these brake disks so that we could ask them what sort of alloy these components use. There aren't even pictures of it – implying the company does not want competitors seeing it too much at this point. The explanation for how (and if) they prevent this issue lies in what they’re made of.

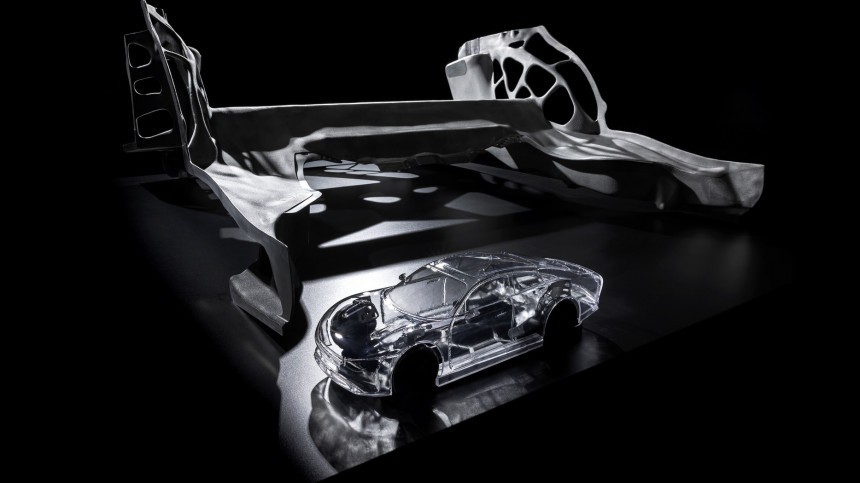

As we said a while ago, the VISION EQXX would have large cast parts. What we did not know is that they would be part of the weight reduction efforts. The structures were developed following bionic engineering principles, which dictate that there should be no material where it is not needed. This is why the castings present hollow spaces. Mercedes-Benz even gave these cast parts special names – you only name something you intend to use more than once.

BIONEQXX is how the company calls the rear floor aluminum structure of the concept car. Although the bionic mesh looks great, it would allow water and dust to invade the car. Mercedes-Benz covered the 42 holes with a material developed by UBQ Materials. Made with biomass from food and garden waste, baby nappies, and plastics, each kilogram of UBQ prevents 1.3 kg of garbage from ending up in landfills.

Mercedes-Benz created the 42 UBQ covers with a 3D printer to ensure perfect sealing and sound-deadening properties. The resulting structure is 15% to 20% lighter than those made with stamped and welded steel pieces. That’s a very different approach compared to that Tesla adopted.

The rear and front castings in the Model Y use a manufacturing method that dismisses heat treatments. In other words, the cast parts are allegedly good to go as soon as they cool down. The main idea is to save time. Mercedes-Benz did not disclose if that is also the case for BIONEQXX, but the 42 recesses that have to be covered by UBQ may cancel the manufacturing advantage the casting could represent. It must take time to cover all of them.

Although Mercedes-Benz may develop a method to speed up building BIONEQXX components with UBQ, let’s suppose it will still be an issue. In this case, the tradeoff would be a longer manufacturing time for less mass. Depending on the applications, it may be well worth it.

The other castings are called BIONICAST. Mercedes-Benz used them on the front damper domes – which save 4 kg compared to pressed domes – and the bracket carrying the windshield wipers and motor.

For the areas that would still benefit from stamped parts, Mercedes-Benz adopted MS1500 ultra-high strength martensitic steel. It is not on the doors, made with a mixture of CFRP (carbon-fiber-reinforced plastics) and GFRP with aluminum reinforcements. The lighter components would also be better in crash-energy absorption – a new polyamide foam on the lower edge of the doors helps with that as well.

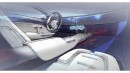

The mass-cutting measures also affected the interior of the VISION EQXX. Instead of door handles, it uses door pulls made from AMsilk’s Biosteel, a synthetic material similar to silk. Instead of leather, it uses Mylo and Deserttex, two materials that are vegan and also lighter. Bamboo and recycled PET also found their way into the concept car’s interior.

Wheels and tires could not be excluded from the weight-reduction mission. The 185/65 R20 Bridgestone Turanza Eco tires were specially developed for the VISION EQXX both to weigh as little as possible and to offer ultra-low rolling resistance. The 20-inch wheels are made of forged magnesium. They will only reach mass-production at a small fortune a pop.

The dissonant note in this quest for a lightweight vehicle came from the solar roof, composed of 117 solar cells. Used to power ancillary systems such as lights and infotainment, it would add up to 25 km (15.5 mi) of range on long-distance journeys on a single day by saving energy, not by adding it to the high-voltage battery pack. The problem with it is that it accumulates the generated energy in an LFP (lithium iron phosphate) battery.

Mercedes-Benz says it is light, but it has a lower energy density than ternary cells normally used to make these auxiliary batteries. That means the German carmaker could have saved weight on that too. If it didn’t, it was probably a decision related to cost – another strong sign that Mercedes-Benz considers mass-production for this car.

The German carmaker only revealed a few more of its secrets to turning the VISION EQXX into an energy efficiency champion. One of them relates to the wheel covers. Made of a semi-transparent material, they prevent turbulence around wheel wells. Active aero-shutters also allow the concept car to have lower drag resistance.

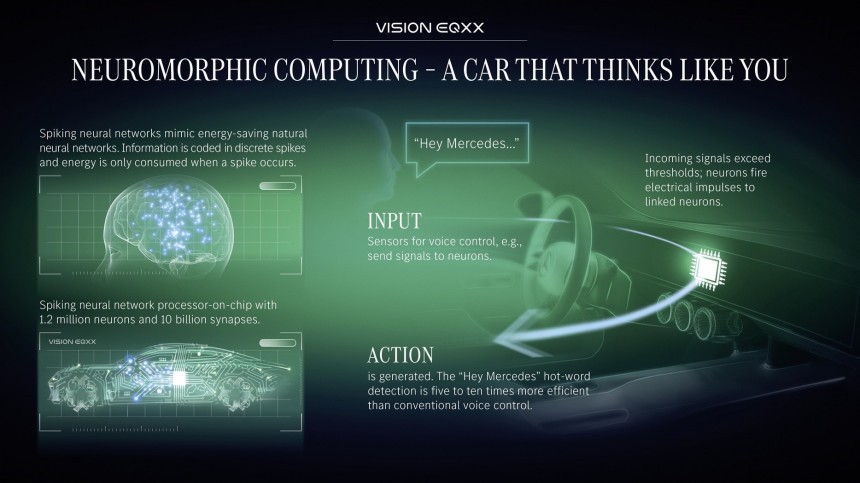

Mercedes-Benz promised software would play a key role in making the VISION EQXX need less energy to move. That task would be with neuromorphic computing. It is way faster than what we have today, implying it will spend less energy performing the same functions. The problem is that it is basically a promise, so it plays no role at all in helping the VISION EQXX.

The only software with that task is the one that aids people to drive the EV more efficiently. It takes into consideration battery status, energy flow, terrain conditions, rolling resistance, and even how the wind is blowing for the driver to make the best decisions. Hopefully, it will also teach them how to preserve the battery pack without the help of liquid cooling.

The VISION EQXX has unique elements, such as GFRP (glass-fiber-reinforced plastic) springs developed with Rheinmetall Automotive. You can see right below that the material they use is not the only surprise they reserve: their format is also pretty uncommon. Mercedes-Benz only mentioned that they are lighter than conventional coil springs but did not refer to their durability.

This text was pretty much ready when Green Car Reports revealed the most controversial aspect of weight reduction in the VISION EQXX: an air-cooled battery pack. Curiously, Mercedes-Benz avoids calling it by what it is as much as possible. It says that the car presents “fully passive cooling,” a cooling plate, water pumps, and a cooling fan, but you have to ask the company how they work to get the whole picture. That’s what we did.

To GCR, Markus Schäfer said that pumping liquids around would demand precious energy for the VISION EQXX to travel further. Daimler’s CTO (chief technology officer) thinks there is no need for liquid cooling thanks to how efficient the electric drivetrain is. Mercedes-Benz includes everything involved with moving the EV – from the battery pack to the wheels – under this classification.

This set of elements would deliver a 95% efficiency. That means that 95% of the electricity used to power the car is converted into movement. This number shows impressive advancements in perfecting the powertrain. It is unclear if working at more than 900V helped the company achieve this result. Unfortunately, Mercedes-Benz did not disclose which measures it took to get there.

For the automaker, a simple cooling plate underneath the battery pack is enough for bringing down the battery pack temperature. The cooling plate does not use any sort of liquid circulation: it is just a metal heat exchange surface. When the car is in hot weather, climbing a steep slope, or stuck in traffic, a cooling fan would kick in but only for the electric drive unit, not for the battery pack.

Although the 150 kW motor makes the VISION EQXX have a relatively low discharge demand rate (1.5 C), this EV would probably need to fast charge every once in a while if it reached mass production. Mercedes-Benz said it could add 300 km (186 mi) of range in 15 minutes. That confirms the battery pack would heat up quite a bit in such situations, immediately reducing charging speed. An insufficiently cooled battery pack would also lose capacity and present reliability issues in the long term.

In short, either Mercedes-Benz found a way to deal with fast-charging effects and did not tell us about that, or it just omitted the problem to solve it if it ever adopts this air-cooled battery pack in production cars. The VISION EQXX suggests that this will be the case.

By deciding to save weight and energy by killing liquid-cooling in this smaller-than-100-kWh battery pack, the automaker prevented any comparison with modern battery packs. All of them are liquid-cooled. The one in the current LEAF was conceived more than ten years ago, and even Nissan gave up on the idea.

If the VISION EQXX’s battery pack was liquid-cooled, we could compare it to similar components to understand the impact that higher silicon content in the anodes made. Mercedes-Benz also said that the separate compartment for electronic components – called OneBox – saved space from squeezing more cells into the battery pack.

Mercedes-Benz’s proposal for the battery pack gets even more questionable after what ONE (Our Next Energy) recently revealed. The battery tech startup disclosed that it developed a battery pack called Gemini 001. After fitting one into a Model S, the EV managed to run 752 mi (1,210.2 km) on a single charge. With liquid cooling, it presents 416-Wh/l and 203.7 kWh, double the energy capacity on the VISION EQXX.

We get it that the new Mercedes-Benz is allegedly just a concept car. In other words, its only mission would be to prove that it is possible to run 1,000 km with a 100 kWh battery pack. However, it seems to be more than that. If the goal was to make something that would never reach assembly lines, why didn’t Mercedes-Benz go with cameras instead of rear-view mirrors? The Honda e adopts cameras because they help it save energy – and it is a production car.

Another controversial aspect of Mercedes-Benz is the adoption of aluminum brake disks. On paper, it looks like a stroke of genius. Apart from being lighter, they are also corrosion-free. That can be really helpful in electric cars because EVs do not use brakes as much as conventional cars due to regenerative braking. Another advantage these brake disks would offer is to reduce brake dust emission by up to 90%.

Here, the problem is that nobody uses aluminum disk brakes for a reason: aluminum expands a lot more than iron when it is exposed to heat. Mercedes-Benz did not reveal who makes these brake disks so that we could ask them what sort of alloy these components use. There aren't even pictures of it – implying the company does not want competitors seeing it too much at this point. The explanation for how (and if) they prevent this issue lies in what they’re made of.

As we said a while ago, the VISION EQXX would have large cast parts. What we did not know is that they would be part of the weight reduction efforts. The structures were developed following bionic engineering principles, which dictate that there should be no material where it is not needed. This is why the castings present hollow spaces. Mercedes-Benz even gave these cast parts special names – you only name something you intend to use more than once.

Mercedes-Benz created the 42 UBQ covers with a 3D printer to ensure perfect sealing and sound-deadening properties. The resulting structure is 15% to 20% lighter than those made with stamped and welded steel pieces. That’s a very different approach compared to that Tesla adopted.

The rear and front castings in the Model Y use a manufacturing method that dismisses heat treatments. In other words, the cast parts are allegedly good to go as soon as they cool down. The main idea is to save time. Mercedes-Benz did not disclose if that is also the case for BIONEQXX, but the 42 recesses that have to be covered by UBQ may cancel the manufacturing advantage the casting could represent. It must take time to cover all of them.

Although Mercedes-Benz may develop a method to speed up building BIONEQXX components with UBQ, let’s suppose it will still be an issue. In this case, the tradeoff would be a longer manufacturing time for less mass. Depending on the applications, it may be well worth it.

The other castings are called BIONICAST. Mercedes-Benz used them on the front damper domes – which save 4 kg compared to pressed domes – and the bracket carrying the windshield wipers and motor.

For the areas that would still benefit from stamped parts, Mercedes-Benz adopted MS1500 ultra-high strength martensitic steel. It is not on the doors, made with a mixture of CFRP (carbon-fiber-reinforced plastics) and GFRP with aluminum reinforcements. The lighter components would also be better in crash-energy absorption – a new polyamide foam on the lower edge of the doors helps with that as well.

Wheels and tires could not be excluded from the weight-reduction mission. The 185/65 R20 Bridgestone Turanza Eco tires were specially developed for the VISION EQXX both to weigh as little as possible and to offer ultra-low rolling resistance. The 20-inch wheels are made of forged magnesium. They will only reach mass-production at a small fortune a pop.

The dissonant note in this quest for a lightweight vehicle came from the solar roof, composed of 117 solar cells. Used to power ancillary systems such as lights and infotainment, it would add up to 25 km (15.5 mi) of range on long-distance journeys on a single day by saving energy, not by adding it to the high-voltage battery pack. The problem with it is that it accumulates the generated energy in an LFP (lithium iron phosphate) battery.

Mercedes-Benz says it is light, but it has a lower energy density than ternary cells normally used to make these auxiliary batteries. That means the German carmaker could have saved weight on that too. If it didn’t, it was probably a decision related to cost – another strong sign that Mercedes-Benz considers mass-production for this car.

The German carmaker only revealed a few more of its secrets to turning the VISION EQXX into an energy efficiency champion. One of them relates to the wheel covers. Made of a semi-transparent material, they prevent turbulence around wheel wells. Active aero-shutters also allow the concept car to have lower drag resistance.

Mercedes-Benz promised software would play a key role in making the VISION EQXX need less energy to move. That task would be with neuromorphic computing. It is way faster than what we have today, implying it will spend less energy performing the same functions. The problem is that it is basically a promise, so it plays no role at all in helping the VISION EQXX.