Daimler Truck has big plans for sustainable and zero-emission transportation. Not only is it playing a major role in bringing electric trucks on the market, but it also plans to focus on the two major all-electric drive technologies, battery and hydrogen-based fuel cell, and completely transform its current production plants.

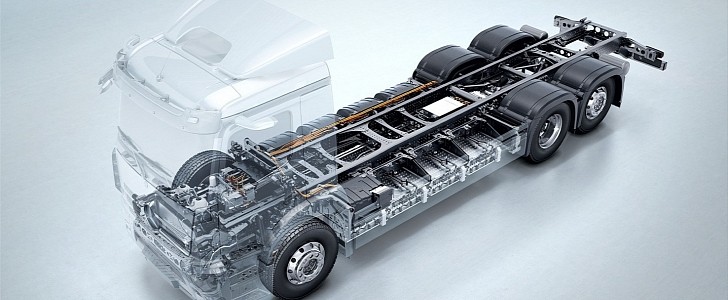

The Mercedes-Benz eActros recently made its digital debut, and will go into series production at the Worth plant, starting October 2021. The eEconic, which is currently undergoing testing, will follow next year, and the eActros for long-distance transport will start being manufactured by the middle of the decade. In order to roll out this ambitious plan, Daimler will also manufacture the key components for electric trucks at its powertrain plants.

The Mercedes-Benz plant in Gaggenau, which is focused on heavy-duty truck transmissions, will be turned into a “competence center” for electric drive components and hydrogen-based fuel cell drive components. The Mercedes-Benz plant in Kassel will expand its competencies from commercial vehicle axle to electric drive systems. Lastly, the Mercedes-Benz plant in Mannheim, specializing in engines, will focus on battery technologies and high-voltage-systems.

In addition to the competence centers that will be set up at these plants, Daimler will also introduce innovation laboratories ("InnoLabs") that will focus on developing production processes and technologies. This way, the transition from prototype production to series development will be accelerated. The "InnoLab Battery” at the Mercedes-Benz plant in Mannheim is set to play a particularly important role as the company’s pilot battery cell production center.

The plan is to gradually transform these three facilities, from combustion engine technologies to production plants with competence centers for electric drive components, including hydrogen-based fuel cell drives and battery technologies.

Another key aspect is that the powertrain plants themselves will become CO2-neutral starting form next year, aligning with the other European Daimler Truck plants. By purchasing electricity from local wind, solar and hydropower plants, Daimler’s powertrain plants will ensure a clean basis for CO2-neutral production.

The Mercedes-Benz plant in Gaggenau, which is focused on heavy-duty truck transmissions, will be turned into a “competence center” for electric drive components and hydrogen-based fuel cell drive components. The Mercedes-Benz plant in Kassel will expand its competencies from commercial vehicle axle to electric drive systems. Lastly, the Mercedes-Benz plant in Mannheim, specializing in engines, will focus on battery technologies and high-voltage-systems.

In addition to the competence centers that will be set up at these plants, Daimler will also introduce innovation laboratories ("InnoLabs") that will focus on developing production processes and technologies. This way, the transition from prototype production to series development will be accelerated. The "InnoLab Battery” at the Mercedes-Benz plant in Mannheim is set to play a particularly important role as the company’s pilot battery cell production center.

The plan is to gradually transform these three facilities, from combustion engine technologies to production plants with competence centers for electric drive components, including hydrogen-based fuel cell drives and battery technologies.

Another key aspect is that the powertrain plants themselves will become CO2-neutral starting form next year, aligning with the other European Daimler Truck plants. By purchasing electricity from local wind, solar and hydropower plants, Daimler’s powertrain plants will ensure a clean basis for CO2-neutral production.