During an era when a cast iron block was the main ingredient for building mass-produced internal combustion engines, General Motors' Buick division unleased an all-aluminum V8 that revolutionized the automotive industry worldwide.

Iron has been used by humans for thousands of years. At first, it was used to make simple weapons and tools, but since it was first smelted, the metal was at the core of our evolution.

During the last three centuries, iron became more important than ever. Thanks to its strength, durability, and abundance, it was one of the catalysts of the industrial revolution.

Naturally, the automotive industry has benefited from using iron since its emergence during the last decades of the 19th century. The first internal combustion engines were built around blocks made out of iron, specifically cast iron alloys. Though automobiles – and consequently their engines – evolved considerably during the 20th, cast iron remained the base alloy for engine block manufacturing.

However, the brightest engineering minds realized that the only major drawback of cast iron was its weight. So they gradually replaced it with aluminum alloys, which led to the lightweight all-aluminum units that are widespread today.

Prototype aluminum block engines have been around for centuries. One of the very first was developed by Karl Benz, the father of the automobile. Nevertheless, metalworking limitations and high production costs didn't make aluminum a viable, mass-production-worthy alternative to cast iron for decades to come.

That started to change after the Second World War when various European manufacturers began experimenting with aluminum engine blocks again.

Inspired by the efforts of their colleagues across the Atlantic, American engineers also began developing all-aluminum prototypes during that period.

After several successful proof-of-concept designs developed during the early-1950s, GM's engineering department led by Buick engine wizard Joe Turlay (the man behind Buick's Nailhead V8) created the first large-scale production all-aluminum V8 proving its viability and starting a new chapter in the engine design handbook.

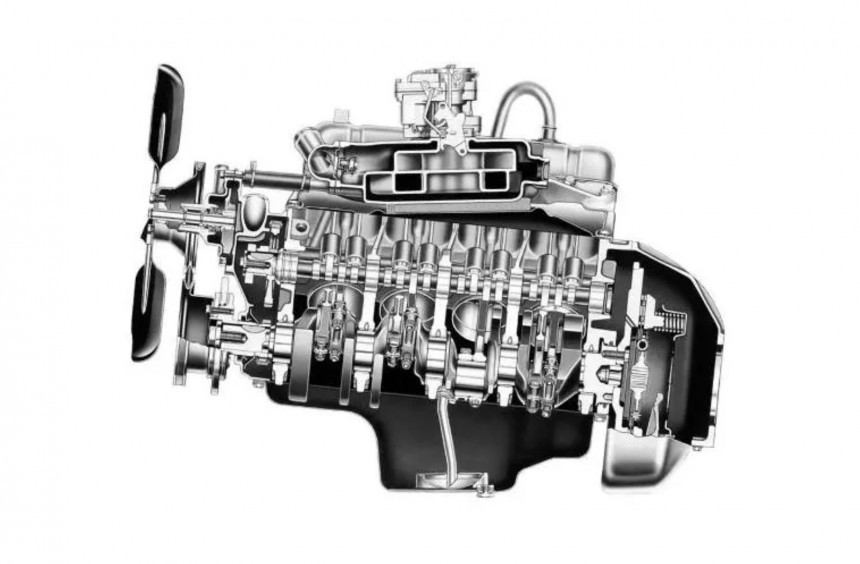

Unveiled in 1960 for the 1961 model year Buick, Pontiac, and Oldsmobile senior compact lineup (hence the BOP nickname), the new engine was a relatively typical overhead cam (OHV) pushrod V8 design, yet it tipped the scales at just 317 pounds (144 kg), which made it considerably lighter than any production V8 on the market and even lighter than most mass-produced four-cylinders of the era.

The secret that made the block viable for mass production was a hybrid semi-permanent molding process that used molds to form the exterior of the block. At the same time, the coolant passageways were created using sand cores, while the eight iron cylinder liners were cast when the block was poured into the molds.

The aluminum alloy used contained 11 to 13 % silicon and about 1% copper. It was a patented GM recipe codenamed GM 4097-M.

Though it displaced 215 cubic inches (3.5 liters), just like a previous, all-aluminum prototype at the heart of the 1951 GM Le Sabre and Buick XP300 concept cars, the BOP 215 was a completely new design. It didn't employ a supercharger, and its 3.5 in x 2.8 in (88.9 mm x 71.1 mm) bore/stroke ratio was oversquare compared to the prototype unit's square design. Apart from the all-aluminum construction, the only significant design similarity between the two motors was the use of hemispherical combustion chambers.

The BOP debuted in the 1961 Buick Special, Pontiac Tempest, and Oldsmobile F-85. It initially had an 8.8:1 compression ratio and featured a Rochester 2GC (DualJet) two-barrel carburetor that enabled it to produce 155 hp. A mid-year upgrade for the Buick Special Skylark introduced a four-barrel carb and a compression bump to 10.0:1, which upped its output to 185 hp.

While the two-barrel carb version remained unchanged, the four-barrel received two additional upgrades in 1962 and 1963. Subsequently, its output rose again, first to 190 hp, then finally reaching 200 hp.

Though it was a game-changer in terms of lightweight construction, the BOP 215 was only produced until 1963. Its short lifespan was caused by high production costs and poor reliability caused partly by block-casting porosity issues.

During the 215's lifecycle, Buick and Pontiac used identical engine versions, while Oldsmobile was given the liberty of slightly modifying its variant. Called Rockette, the Olds unit featured revised cylinder heads, valve covers, and an extra row of head bolts. These changes were primarily cosmetic, making the 215 resemble the highly-successful Rocket V8, so the Rockette had the same output ratings as its Buick and Pontiac siblings.

But Oldsmobile was also responsible for creating the most powerful version of the 215. It was Called Turbo-Rocket, and it came with a novel Garrett AiResearch turbocharger that enabled it to make 215 hp.

It was the first turbocharged production engine used in a passenger car: the 1962 Cutlass-based Oldsmobile Jetfire.

Even if it didn't survive for long in the North American market, the BOP had a long-lasting impact on the automotive industry.

Its architecture was carried over to a revised cast-iron block 300-ci (4.9-liter) in 1964. This version grew in displacement over the years and powered most of Buick's models until it was discontinued in 1977.

Moreover, the BOP design was used to create the Fireball V6 in 1962. Though it featured a cast-iron block and cylinder heads, the engine was basically a 215 with two fewer cylinders. Used on several GM and Jeep models throughout the years, the Fireball V6 morphed into the 3800 during the 1980s, and in this modern guise, it became one of the best, most reliable engines ever built.

After it was discontinued in the US, the original, all-aluminum 215 version lived a long and prosperous life in the UK. Rights for the design were brought by Rover, who continued to produce and improve it until 2004. Its lightweight engine block was also used as the base for the Repco-Brabham 620 Formula 1 V8 in 1966. Thanks to this unit, Jack Brabham won the Drivers' title that year while his team finished first in the Constructors' standings.

Although it was never extremely powerful and had a short lifespan in the US, Buick's 215 was a revolutionary unit that marked a milestone for all-aluminum engines.

If you would like to learn more about this legendary engine, I recommend watching the YouTube video below by Uncle Tony's Garage.

During the last three centuries, iron became more important than ever. Thanks to its strength, durability, and abundance, it was one of the catalysts of the industrial revolution.

Naturally, the automotive industry has benefited from using iron since its emergence during the last decades of the 19th century. The first internal combustion engines were built around blocks made out of iron, specifically cast iron alloys. Though automobiles – and consequently their engines – evolved considerably during the 20th, cast iron remained the base alloy for engine block manufacturing.

However, the brightest engineering minds realized that the only major drawback of cast iron was its weight. So they gradually replaced it with aluminum alloys, which led to the lightweight all-aluminum units that are widespread today.

An evolution that kickstarted an industry-wide revolution

That started to change after the Second World War when various European manufacturers began experimenting with aluminum engine blocks again.

Inspired by the efforts of their colleagues across the Atlantic, American engineers also began developing all-aluminum prototypes during that period.

After several successful proof-of-concept designs developed during the early-1950s, GM's engineering department led by Buick engine wizard Joe Turlay (the man behind Buick's Nailhead V8) created the first large-scale production all-aluminum V8 proving its viability and starting a new chapter in the engine design handbook.

The iconic BOP 215

The secret that made the block viable for mass production was a hybrid semi-permanent molding process that used molds to form the exterior of the block. At the same time, the coolant passageways were created using sand cores, while the eight iron cylinder liners were cast when the block was poured into the molds.

The aluminum alloy used contained 11 to 13 % silicon and about 1% copper. It was a patented GM recipe codenamed GM 4097-M.

Though it displaced 215 cubic inches (3.5 liters), just like a previous, all-aluminum prototype at the heart of the 1951 GM Le Sabre and Buick XP300 concept cars, the BOP 215 was a completely new design. It didn't employ a supercharger, and its 3.5 in x 2.8 in (88.9 mm x 71.1 mm) bore/stroke ratio was oversquare compared to the prototype unit's square design. Apart from the all-aluminum construction, the only significant design similarity between the two motors was the use of hemispherical combustion chambers.

The BOP debuted in the 1961 Buick Special, Pontiac Tempest, and Oldsmobile F-85. It initially had an 8.8:1 compression ratio and featured a Rochester 2GC (DualJet) two-barrel carburetor that enabled it to produce 155 hp. A mid-year upgrade for the Buick Special Skylark introduced a four-barrel carb and a compression bump to 10.0:1, which upped its output to 185 hp.

While the two-barrel carb version remained unchanged, the four-barrel received two additional upgrades in 1962 and 1963. Subsequently, its output rose again, first to 190 hp, then finally reaching 200 hp.

Morphing into the automotive world's first production turbo engine

During the 215's lifecycle, Buick and Pontiac used identical engine versions, while Oldsmobile was given the liberty of slightly modifying its variant. Called Rockette, the Olds unit featured revised cylinder heads, valve covers, and an extra row of head bolts. These changes were primarily cosmetic, making the 215 resemble the highly-successful Rocket V8, so the Rockette had the same output ratings as its Buick and Pontiac siblings.

But Oldsmobile was also responsible for creating the most powerful version of the 215. It was Called Turbo-Rocket, and it came with a novel Garrett AiResearch turbocharger that enabled it to make 215 hp.

It was the first turbocharged production engine used in a passenger car: the 1962 Cutlass-based Oldsmobile Jetfire.

A long-lasting impact on future engine designs

Its architecture was carried over to a revised cast-iron block 300-ci (4.9-liter) in 1964. This version grew in displacement over the years and powered most of Buick's models until it was discontinued in 1977.

Moreover, the BOP design was used to create the Fireball V6 in 1962. Though it featured a cast-iron block and cylinder heads, the engine was basically a 215 with two fewer cylinders. Used on several GM and Jeep models throughout the years, the Fireball V6 morphed into the 3800 during the 1980s, and in this modern guise, it became one of the best, most reliable engines ever built.

After it was discontinued in the US, the original, all-aluminum 215 version lived a long and prosperous life in the UK. Rights for the design were brought by Rover, who continued to produce and improve it until 2004. Its lightweight engine block was also used as the base for the Repco-Brabham 620 Formula 1 V8 in 1966. Thanks to this unit, Jack Brabham won the Drivers' title that year while his team finished first in the Constructors' standings.

Although it was never extremely powerful and had a short lifespan in the US, Buick's 215 was a revolutionary unit that marked a milestone for all-aluminum engines.

If you would like to learn more about this legendary engine, I recommend watching the YouTube video below by Uncle Tony's Garage.