It's a done deal. The future of automobiles is electric. For city air travel, The Jetsons animation kind of reality isn't too far, thanks to eVTOLs (Electric Vertical Take-off and Landing Vehicles). Like any other transformative technology, the obstacles seem unachievable. But if history has taught us anything – in due cause, humanity will find a solution.

In May 2022, Joby Aviation was certified by the FAA (Federal Aviation Administration) to kick-start its eVTOL air taxi operations commercially.

Like EVs, eVTOLs rely on electric propulsion. Simply put, these are battery-electric air vessels.

The eVTOL aircraft operator's progress is a big deal considering the company was founded in 2009. If memory serves us right, it was a year after Tesla released its first car, the Tesla Roadster. During that era, electric cars weren't even part of the automotive discourse.

The main advantage of eVTOLs is the ability to pop around in congested cities and move to places pretty quickly. As such, Joby Aviation is carving out a new transportation industry away from traditional general aviation, big commercial planes, and helicopter service.

Kirsten Dirksen of Kirsten Dirksen YouTube Channel recently got to tour Joby Aviation at Marina Municipal Airport, California, and witnessed a live hovering demonstration.

"So this is one of the advantages of electric propulsion, so you can tune it to run a very tight loop on the controls. And then you have a lot of bandwidth with the electric motors and all the electric actuators, so you can end up with these remarkably smooth flights," a Joby Aviation representative explained.

It's essential to note that Joby Aviation's production prototype is, in fact, designed like a traditional aircraft. It has your conventional aircraft wing and tail. It runs on six propellers with two flying positions, taking off vertically and, when in the air, flying on the wing.

All six propellers on the electric aircraft work independently (articulate independently). When they are all pointing upward, the plane takes up vertically to the point where it's hovering (thrustborne flight). To fly forward, all six propellers articulate, moving 90 degrees.

But unlike your conventional aircraft, Joby Aviation's eVTOL has been designed to be remarkably quiet.

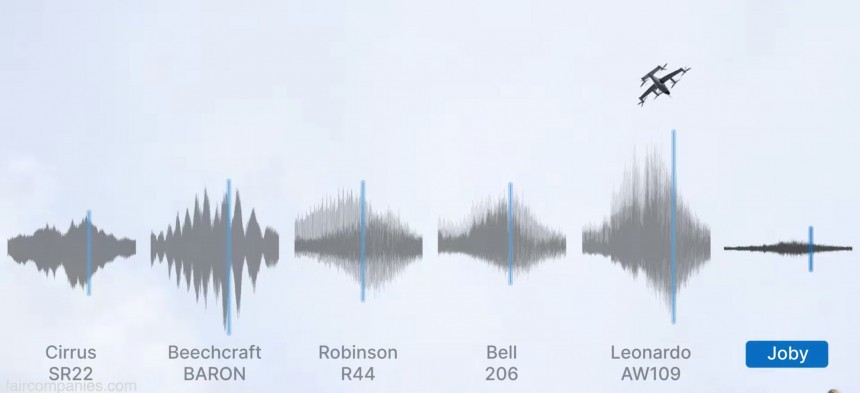

They even conducted a noise level experiment to prove how quiet their eVTOL was compared to a conventional aircraft.

The eVTOL manufacturer flew their plane over at the same speed and altitude and compared the noise produced with a Cirrus SR22, Beechcraft BARON, Robinson R44, Bell 206, and Leonardo AW109. Their aircraft produced the lowest sound levels across the board.

"When the plane is taking off vertically, we're about 65 dBA which is akin to the conversation that we are having right now. When we are flying over at 500 meters, we're like 45 dBA, and that's closer to a sound in the library," Joby Aviation representative revealed.

Joby's battery-electric aircraft has a range of 150 miles (241 kilometers), with the average expected regular mission between 20 miles (32 kilometers) and 25 miles (40 kilometers).

Joby could have taken the easy way out and just developed a big drone for humans. Instead, they decided to make an aircraft first. According to their design team, making the aircraft first is a lot more of a useful platform.

Since they used a traditional aircraft design that included a tail and a wing (with all the complexities), they were able to maximize range and improve on speed. According to the Joby Aviation representative, their battery-electric aircraft is allegedly capable of speeds up to 200 mph (322 kph).

The eVTOL manufacturer didn't stumble upon those numbers by luck. The representative told Dirksen they went through several concepts over the years before landing on the production prototype.

If we've learned anything from race cars, we know the lighter the vehicle parts, the better the performance.

Since they were developing a battery-electric airplane, the airframe needed to be lightweight. As a result, Joby Aviation made production-level composite parts for the airframe with carbon fiber (maximize range and performance).

Joby Aviation seems to have stumbled upon a lucrative industry, but let's take some time to evaluate their struggles moving forward.

Joby Aviation may have acquired an FAA certification, but there are still a lot of hurdles to overcome. Like other startups, the newly crafted transportation industry is still facing technical issues such as battery life, safe operations, and whether it would be a viable option to go autonomous.

That's not all. The biggest hurdle eVTOLs may face is an already congested air space. You probably already know eVTOLs won't be competing against giant airlines for airspace since they operate in low altitudes, but other eVTOLs and drones are in the same space. Add the option for autonomous operations and you’ll have created another hurdle altogether that could take considerable time to overcome.

Also, you can't call an eVTOL service and ask them to pull up next to any street. The newly carved-out industry requires infrastructure like passenger terminals. Think of it as a tiny airport for electric aircraft.

Despite the foreseeable obstacles, Joby Aviation is moving fast and will likely begin operations as short-haul taxis in urban spaces. According to Bloomberg News, the eVTOL manufacturer is already locking up leases on rooftops where its electric propulsion airplanes will land as early as 2024.

Joby Aviation has also developed modular airports for their planes that passengers can access from the street, complete with a lounge (waiting area).

So, how many of these were possible 20 years ago? According to the Joby Aviation representative, battery electric aviation tech was available, with the only shortfall being accessibility.

Over the last ten years, it has become much easier for companies like Joby to access some of the bigger tools needed for manufacturing that were historically difficult to acquire.

In the past, companies had to make a CAD design and contract an aviation engineering company to make the parts for assembly. Joby Aviation get to be ahead of the pack not because they started early but because they have control over the entire production process.

Are curious how an eVTOL takes off, or how they are assembled? We recommend catching that action and more in the video below.

Like EVs, eVTOLs rely on electric propulsion. Simply put, these are battery-electric air vessels.

The eVTOL aircraft operator's progress is a big deal considering the company was founded in 2009. If memory serves us right, it was a year after Tesla released its first car, the Tesla Roadster. During that era, electric cars weren't even part of the automotive discourse.

The main advantage of eVTOLs is the ability to pop around in congested cities and move to places pretty quickly. As such, Joby Aviation is carving out a new transportation industry away from traditional general aviation, big commercial planes, and helicopter service.

"So this is one of the advantages of electric propulsion, so you can tune it to run a very tight loop on the controls. And then you have a lot of bandwidth with the electric motors and all the electric actuators, so you can end up with these remarkably smooth flights," a Joby Aviation representative explained.

It's essential to note that Joby Aviation's production prototype is, in fact, designed like a traditional aircraft. It has your conventional aircraft wing and tail. It runs on six propellers with two flying positions, taking off vertically and, when in the air, flying on the wing.

All six propellers on the electric aircraft work independently (articulate independently). When they are all pointing upward, the plane takes up vertically to the point where it's hovering (thrustborne flight). To fly forward, all six propellers articulate, moving 90 degrees.

But unlike your conventional aircraft, Joby Aviation's eVTOL has been designed to be remarkably quiet.

They even conducted a noise level experiment to prove how quiet their eVTOL was compared to a conventional aircraft.

The eVTOL manufacturer flew their plane over at the same speed and altitude and compared the noise produced with a Cirrus SR22, Beechcraft BARON, Robinson R44, Bell 206, and Leonardo AW109. Their aircraft produced the lowest sound levels across the board.

Joby's battery-electric aircraft has a range of 150 miles (241 kilometers), with the average expected regular mission between 20 miles (32 kilometers) and 25 miles (40 kilometers).

Joby could have taken the easy way out and just developed a big drone for humans. Instead, they decided to make an aircraft first. According to their design team, making the aircraft first is a lot more of a useful platform.

Since they used a traditional aircraft design that included a tail and a wing (with all the complexities), they were able to maximize range and improve on speed. According to the Joby Aviation representative, their battery-electric aircraft is allegedly capable of speeds up to 200 mph (322 kph).

The eVTOL manufacturer didn't stumble upon those numbers by luck. The representative told Dirksen they went through several concepts over the years before landing on the production prototype.

If we've learned anything from race cars, we know the lighter the vehicle parts, the better the performance.

Joby Aviation seems to have stumbled upon a lucrative industry, but let's take some time to evaluate their struggles moving forward.

Joby Aviation may have acquired an FAA certification, but there are still a lot of hurdles to overcome. Like other startups, the newly crafted transportation industry is still facing technical issues such as battery life, safe operations, and whether it would be a viable option to go autonomous.

That's not all. The biggest hurdle eVTOLs may face is an already congested air space. You probably already know eVTOLs won't be competing against giant airlines for airspace since they operate in low altitudes, but other eVTOLs and drones are in the same space. Add the option for autonomous operations and you’ll have created another hurdle altogether that could take considerable time to overcome.

Also, you can't call an eVTOL service and ask them to pull up next to any street. The newly carved-out industry requires infrastructure like passenger terminals. Think of it as a tiny airport for electric aircraft.

Despite the foreseeable obstacles, Joby Aviation is moving fast and will likely begin operations as short-haul taxis in urban spaces. According to Bloomberg News, the eVTOL manufacturer is already locking up leases on rooftops where its electric propulsion airplanes will land as early as 2024.

Joby Aviation has also developed modular airports for their planes that passengers can access from the street, complete with a lounge (waiting area).

So, how many of these were possible 20 years ago? According to the Joby Aviation representative, battery electric aviation tech was available, with the only shortfall being accessibility.

In the past, companies had to make a CAD design and contract an aviation engineering company to make the parts for assembly. Joby Aviation get to be ahead of the pack not because they started early but because they have control over the entire production process.

Are curious how an eVTOL takes off, or how they are assembled? We recommend catching that action and more in the video below.