In December 2022, SAE International published the first standardization guidelines for wireless power transfer up to 500 kW power, aimed at heavy-duty vehicles. A few months later, Chalmers University in Sweden has already developed a high-power inductive charging system that “can soon be presented to industry.”

Back in 2018, the Department of Energy’s Oak Ridge National Laboratory demonstrated a 120-kW wireless charging system with 97% efficiency. It was a huge step in terms of power transferred through air, with no plug-in connectors.

Following this demonstration, in 2021, ORNL developed a unique polyphase electromagnetic coil, capable of delivering 1.5 MW per square meter. All of this was possible thanks to the latest silicon carbide technology, which made possible a new coil design.

The new high-power semiconductors based on silicon carbide, which are also known as SiC, allow much higher voltage and temperatures, and much higher switching frequency. The classic silicon components are capable of frequencies of around 20 kHz, while SiC power electronics allow up to 90 kHz.

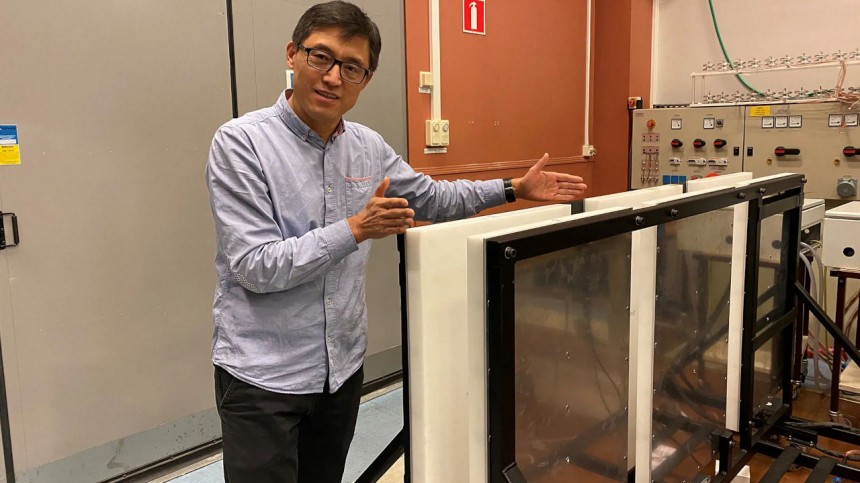

Researchers of Chalmers University in Goteborg, the second largest city in Sweden after Stockholm, add another ingredient. They replaced classic copper coils with intertwined copper microfibers. One such ‘copper rope’ is made of up to 10,000 fibers between 70 and 100 micrometers thick, which is as thin as a strand of hair.

Copper wires convert energy into oscillating magnetic fields, and very high frequencies generate a lot of heat. This is ok for induction cookers in the kitchen, but in the case of wireless charging a big part of the energy to be transferred is lost. Thus, efficiency is much lower than plug-in charging.

But now technological advancement made it possible for the industry to come up with these new braided 'copper ropes'. The so-called litz wire has been commercially available for just a few years, but it already is the best solution for high currents and frequencies.

Heat losses are minimum and they are just a few percent higher than similar high-power conductive charging. But the latter requires some sort of contact between the transmitter and receiver coils, and that’s why high-power induction charging is much more interesting.

Chalmer researchers’ system is capable to transfer 500 kW per 2 square meters with a 15 cm (6 in.) air gap between the two coil pads. It’s not as impressive as ORNL’s 1,500 kW per square meter, but it has better efficiency of 98%.

Moreover, Chalmer researchers used a new type of capacitors for building up a more powerful magnetic field. This is helpful in the conversion steps for charging a battery, like direct current (DC) to alternating current (AC) or between different voltage levels.

For now, it’s not suitable for light-duty vehicles, because the main goal of this research project was aimed at very large transport vehicles, like diesel-powered ferries or city buses and heavy trucks, or the new kind of driverless electric vehicles used in industry, mining, and agriculture.

Yujing Liu, Professor of Electrical Power Engineering at the Department of Electrical Engineering, Chalmers: “You can have a system built into the wharf that charges the ferry at some stops, at the same time as passengers get on and off. Automatic and completely independent of weather and wind, charging can take place 30-40 times per day.”

Or think about a Tesla Semi and its massive ~900 kWh battery pack. Fast charging such a big battery requires a very thick and heavy charging cable, difficult to handle. Then there’s high pressure on the plug-in connectors because of high voltage currents and all sorts of other possible issues related to electronic management.

The 500-kW wireless system is much more appropriate in terms of convenience. And it doesn’t require too many modifications on the vehicle for seamless integration. Of course, if Elon Musk will find this solution interesting, it will probably be upgraded spectacularly.

For now, it seems that Chalmer’s high-power wireless system is among the best in the world in terms of efficiency. For instance, Pennsylvania-based Momentum Dynamics, which recently became InductEV, is testing a 450-kW wireless charging system together with the Chinese Geely Group.

In the meantime, ORNL licensed its high-power wireless charging technology to Brooklyn-based HEVO. After co-developing a feasible 300-kW charging system, the next step is for half a megawatt or more system. ORNL is also working with VW Group for 300-kW wireless charging systems, while HEVO partnered with Stellantis to explore wireless charging capabilities.

So, the race for 500-kW wireless charging systems is heating up. It’s just a matter of time until a production-ready system with even higher power will become reality. It’s then necessary for SAE International to upgrade its standardization guidelines to 1,000 kW or more.

Wireless charging technology evolves fascinating for experts in this field. As I pointed out in a recent series of articles, inductive charging has much more chance to become a game changer for EVs than conductive charging or battery swapping.

The next few years will be critical for all the demonstration projects to rise to expectations. By the end of the decade, wide implementation of wireless charging in the transportation sector could turn upside down all the forecasts for battery manufacturing and electric vehicle adoption. In a very good way, that is.

Following this demonstration, in 2021, ORNL developed a unique polyphase electromagnetic coil, capable of delivering 1.5 MW per square meter. All of this was possible thanks to the latest silicon carbide technology, which made possible a new coil design.

The new high-power semiconductors based on silicon carbide, which are also known as SiC, allow much higher voltage and temperatures, and much higher switching frequency. The classic silicon components are capable of frequencies of around 20 kHz, while SiC power electronics allow up to 90 kHz.

Researchers of Chalmers University in Goteborg, the second largest city in Sweden after Stockholm, add another ingredient. They replaced classic copper coils with intertwined copper microfibers. One such ‘copper rope’ is made of up to 10,000 fibers between 70 and 100 micrometers thick, which is as thin as a strand of hair.

But now technological advancement made it possible for the industry to come up with these new braided 'copper ropes'. The so-called litz wire has been commercially available for just a few years, but it already is the best solution for high currents and frequencies.

Heat losses are minimum and they are just a few percent higher than similar high-power conductive charging. But the latter requires some sort of contact between the transmitter and receiver coils, and that’s why high-power induction charging is much more interesting.

Chalmer researchers’ system is capable to transfer 500 kW per 2 square meters with a 15 cm (6 in.) air gap between the two coil pads. It’s not as impressive as ORNL’s 1,500 kW per square meter, but it has better efficiency of 98%.

Moreover, Chalmer researchers used a new type of capacitors for building up a more powerful magnetic field. This is helpful in the conversion steps for charging a battery, like direct current (DC) to alternating current (AC) or between different voltage levels.

For now, it’s not suitable for light-duty vehicles, because the main goal of this research project was aimed at very large transport vehicles, like diesel-powered ferries or city buses and heavy trucks, or the new kind of driverless electric vehicles used in industry, mining, and agriculture.

Yujing Liu, Professor of Electrical Power Engineering at the Department of Electrical Engineering, Chalmers: “You can have a system built into the wharf that charges the ferry at some stops, at the same time as passengers get on and off. Automatic and completely independent of weather and wind, charging can take place 30-40 times per day.”

The 500-kW wireless system is much more appropriate in terms of convenience. And it doesn’t require too many modifications on the vehicle for seamless integration. Of course, if Elon Musk will find this solution interesting, it will probably be upgraded spectacularly.

For now, it seems that Chalmer’s high-power wireless system is among the best in the world in terms of efficiency. For instance, Pennsylvania-based Momentum Dynamics, which recently became InductEV, is testing a 450-kW wireless charging system together with the Chinese Geely Group.

In the meantime, ORNL licensed its high-power wireless charging technology to Brooklyn-based HEVO. After co-developing a feasible 300-kW charging system, the next step is for half a megawatt or more system. ORNL is also working with VW Group for 300-kW wireless charging systems, while HEVO partnered with Stellantis to explore wireless charging capabilities.

So, the race for 500-kW wireless charging systems is heating up. It’s just a matter of time until a production-ready system with even higher power will become reality. It’s then necessary for SAE International to upgrade its standardization guidelines to 1,000 kW or more.

Wireless charging technology evolves fascinating for experts in this field. As I pointed out in a recent series of articles, inductive charging has much more chance to become a game changer for EVs than conductive charging or battery swapping.

The next few years will be critical for all the demonstration projects to rise to expectations. By the end of the decade, wide implementation of wireless charging in the transportation sector could turn upside down all the forecasts for battery manufacturing and electric vehicle adoption. In a very good way, that is.