No one can question the fact NASA is the world’s leading space exploration organization. Knowing this would have one believe NASA became that because it focuses long and hard on its main area of expertise, space. But that’s far from the truth, and the space agency has been involved in projects that have nothing to do with space for a long time now.

Some of these projects have to do with aviation. We all know NASA’s quest to find a proper way to build a civilian supersonic airliner, or the many ideas it has for the advancement of advanced aerial mobility vehicles (that would be passenger and cargo drones). But this crew is also knee-deep in the research of future propulsion means for aircraft.

One of them is called HyTEC, and stands for Hybrid Thermally Efficient Core. It’s an idea that popped into the heads of NASA engineers back in 2021, and seeks to develop technologies that could help reduce fuel consumption in jet engines, while keeping the same levels of thrust we’re used to and regularly enjoy during our aerial trips.

The ultimate target technology of the HyTEC effort is a smaller core for a turbofan jet engine. One that could be deployed into an engine looking about the same as present-day ones do, while providing a reduction in fuel consumption by up to ten percent. That may not seem all that much, but consider passenger aircraft use tremendous amounts of fuel, and ten percent could mean a lot in the grand scheme of things.

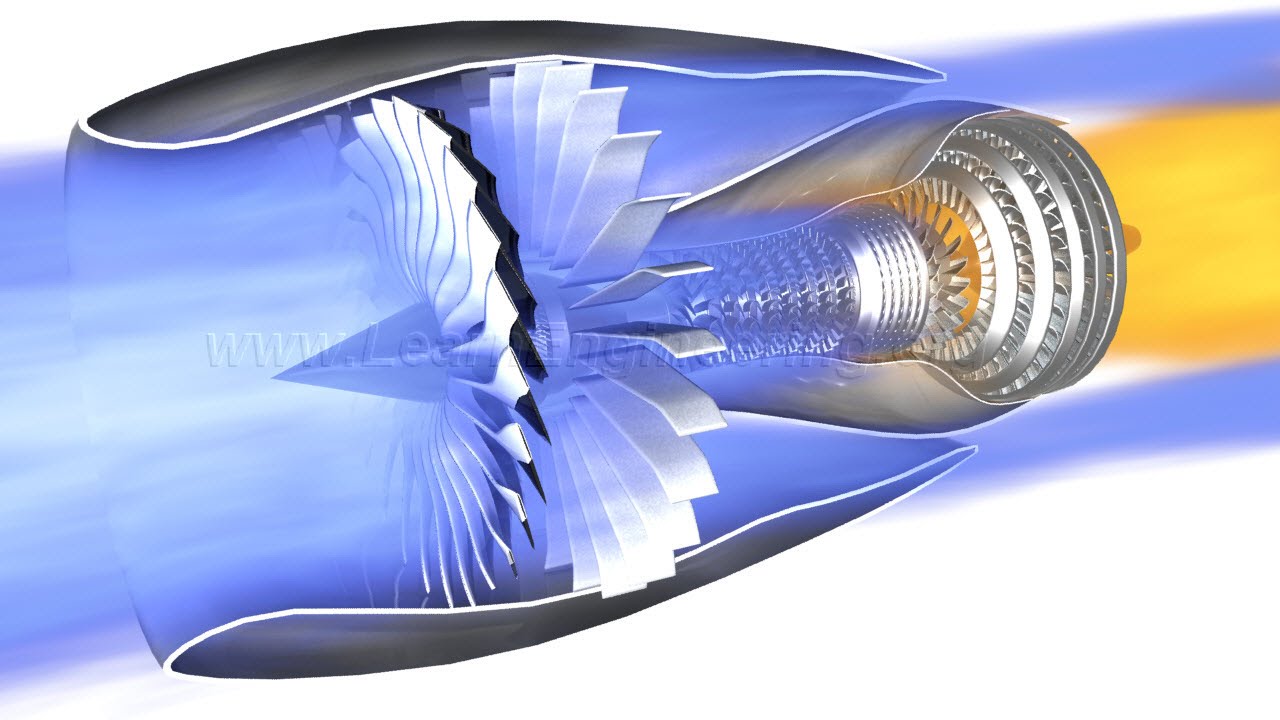

One way to make a jet engine more efficient is simple, and requires the increase in bypass ratio. That is the ratio of how much of the air drawn in by a jet engine’s fan is turned into thrust, and how much of it is used by the engine core for combustion and keep said fan operational.

You see, a jet engine is sort of self-sustaining. That big fan at the front we see most of the time when looking at an airplane is there as a means to draw in as much air as possible, and turn it into thrust by accelerating it and sending out the other end through narrow ducts.

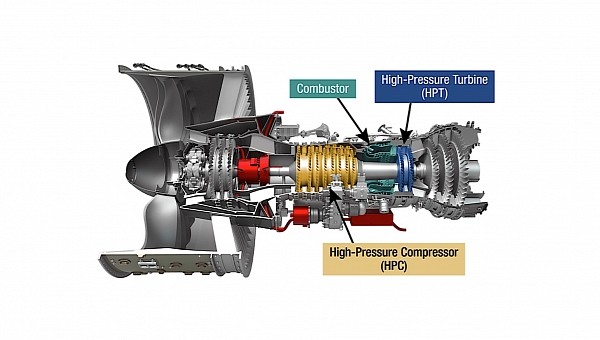

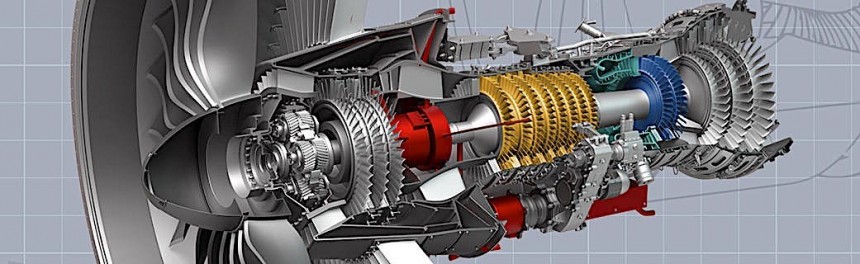

Not all the air going into the engine is turned into this kind of direct thrust – after all, some of it is needed to keep the actual engine running. So some of the air is sent to the engine core, meaning the assembly that contains the compressor, combustion chamber, turbine, and exhaust nozzle.

The air that gets here is compressed, and passed into the combustion chamber, where it is mixed with fuel and ignited. It then moves through the turbine, which also keeps the fan at the front running and drawing in more air for this seemingly endless cycle to repeat itself. A desirable side effect of the engine running is that power is generated and fed to some of the airplane’s critical systems.

So, it’s the bypass ratio NASA is interested in. You see, the organization says at the moment the Boeing 787 Dreamliner is the plane with one of the best bypass ratios out there: 9. What that means is that in its GE engines nine times more air bypasses the engine’s core as thrust instead of entering it to be used for combustion.

What HyTEC is supposed to do is increase that ratio even further, to as much as 15 – meaning 15 times more air will be used for thrust than combustion. Such an approach would of course less fuel being burned, while keeping thrust levels roughly the same. NASA plans to do this not by increasing the size of the fan or changing the design of the overall jet engine, but by decreasing the size of the engine core, all while keeping the same thrust levels.

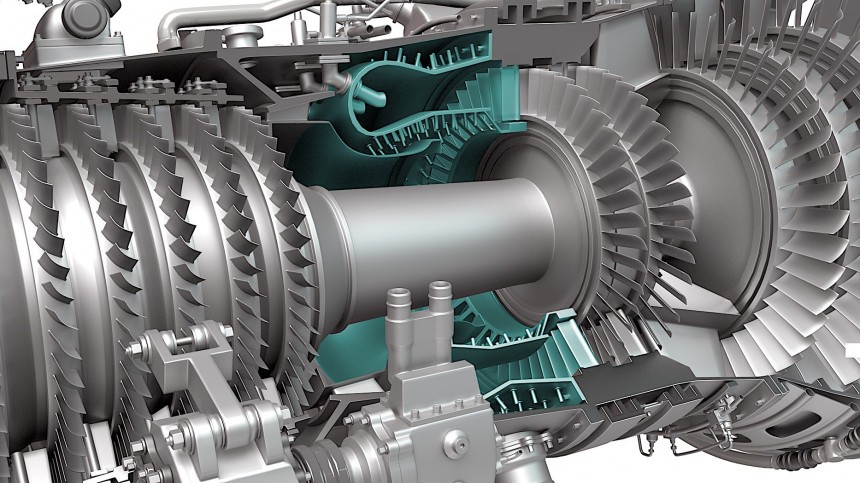

Theoretically, this is possible, but a downsizing of the core poses several distinct challenges. The first concerns the materials that will be used, because a smaller size means more internal pressure and temperature, to the point current materials cannot sustain. Also, dimensions, design ratios and aerodynamics will change, despite the new engine looking essentially the same on the outside.

What that means is a lot of testing will have to be done before seeing if this concept could work. NASA and its partners will have to create and test new materials, like ceramic matrix composites, but also come up with new design ideas and their associated technologies.

A side benefit of the project would be some sort of hybridization for the jet engine. Since it already powers the aircraft’s components (but only just, as the most power an engine gives to electricity is 5 percent, in the Boeing 787 Dreamliner), NASA is looking at pulling “more electrical power from this engine to power other systems aboard the aircraft.” That would be close to 20 percent, which would mean a dramatic jump.

In November last year engine maker Pratt & Whitney joined the HyTEC project, but it didn’t specifically say anything about the tech it is developing, other than it should be able to run on sustainable aviation fuel (SAF).

It’s likely several years will pass before we get the first new engines in the real world, but NASA plans to have them installed in airplanes by the middle of the next decade.

One of them is called HyTEC, and stands for Hybrid Thermally Efficient Core. It’s an idea that popped into the heads of NASA engineers back in 2021, and seeks to develop technologies that could help reduce fuel consumption in jet engines, while keeping the same levels of thrust we’re used to and regularly enjoy during our aerial trips.

The ultimate target technology of the HyTEC effort is a smaller core for a turbofan jet engine. One that could be deployed into an engine looking about the same as present-day ones do, while providing a reduction in fuel consumption by up to ten percent. That may not seem all that much, but consider passenger aircraft use tremendous amounts of fuel, and ten percent could mean a lot in the grand scheme of things.

One way to make a jet engine more efficient is simple, and requires the increase in bypass ratio. That is the ratio of how much of the air drawn in by a jet engine’s fan is turned into thrust, and how much of it is used by the engine core for combustion and keep said fan operational.

Not all the air going into the engine is turned into this kind of direct thrust – after all, some of it is needed to keep the actual engine running. So some of the air is sent to the engine core, meaning the assembly that contains the compressor, combustion chamber, turbine, and exhaust nozzle.

The air that gets here is compressed, and passed into the combustion chamber, where it is mixed with fuel and ignited. It then moves through the turbine, which also keeps the fan at the front running and drawing in more air for this seemingly endless cycle to repeat itself. A desirable side effect of the engine running is that power is generated and fed to some of the airplane’s critical systems.

So, it’s the bypass ratio NASA is interested in. You see, the organization says at the moment the Boeing 787 Dreamliner is the plane with one of the best bypass ratios out there: 9. What that means is that in its GE engines nine times more air bypasses the engine’s core as thrust instead of entering it to be used for combustion.

Theoretically, this is possible, but a downsizing of the core poses several distinct challenges. The first concerns the materials that will be used, because a smaller size means more internal pressure and temperature, to the point current materials cannot sustain. Also, dimensions, design ratios and aerodynamics will change, despite the new engine looking essentially the same on the outside.

What that means is a lot of testing will have to be done before seeing if this concept could work. NASA and its partners will have to create and test new materials, like ceramic matrix composites, but also come up with new design ideas and their associated technologies.

A side benefit of the project would be some sort of hybridization for the jet engine. Since it already powers the aircraft’s components (but only just, as the most power an engine gives to electricity is 5 percent, in the Boeing 787 Dreamliner), NASA is looking at pulling “more electrical power from this engine to power other systems aboard the aircraft.” That would be close to 20 percent, which would mean a dramatic jump.

In November last year engine maker Pratt & Whitney joined the HyTEC project, but it didn’t specifically say anything about the tech it is developing, other than it should be able to run on sustainable aviation fuel (SAF).

It’s likely several years will pass before we get the first new engines in the real world, but NASA plans to have them installed in airplanes by the middle of the next decade.