Now that Porsche is going deeper than ever into the world of turbocharged engines, the German automaker plans to rewrite the rules a little bit. The German engineers are currently on a quest for what has been some sort of an internal combustion engine Holy Grail, namely a variable compression ratio engine.

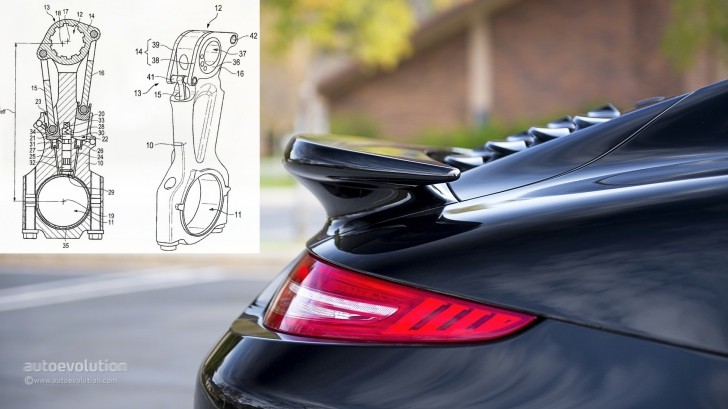

The patent you see above is the result of a collaboration between Porsche Consulting, the company’s consultancy arm, and Hilite International, which produces variable valve timing control components.

The latter is defined as the degree to which the fuel-air mixture is compressed by the piston before ignition. While a higher ratio help an engine achieve superior performance, it can also lead to detonation, which represents the auto-ignition of the fuel mixture before the piston reaches the top of its travel within the cylinder.

While modern powerplants use detonation or knocking sensors to address the issue, with the added boost pressure of a turbocharger, engine designers are forced to reduce the compression ratio. This affects low-rpm efficiency, which brings drawbacks in terms of both mileage and drivability - turbo lag.

Various technical solutions for a variable compression ratio have been proposed for about 100 years now, but these were deemed unfeasible. The idea is to have an engine that can operate at a compression ratio that’s inversely proportional with the boost pressure.

This is where Porsche’s innovation steps in, as the Germans propose a solution that aims to be as simple and therefore as reliable as possible.

Porsche’s system features two positions rather than a range of actuation levels, in order to keep things feasible.

Then again the joint-development means the system could simply be a cash-delivering development that may show up in a vehicle outside the Porsche. This wouldn’t be the first time when the company lends its engineering expertise to another developer. For instance, the Opel Zafira MPV was developed with Porsche assistance.

The basics

Before we allow ourselves to enter Porsche’s variable combustion chamber, we have to discuss the reasons for building such a structure. The industry has now turned to turbocharging in order to increase efficiency as part of the downsizing process and yet forced induction does mean you have to make a compromise in term of the compression ratio.The latter is defined as the degree to which the fuel-air mixture is compressed by the piston before ignition. While a higher ratio help an engine achieve superior performance, it can also lead to detonation, which represents the auto-ignition of the fuel mixture before the piston reaches the top of its travel within the cylinder.

While modern powerplants use detonation or knocking sensors to address the issue, with the added boost pressure of a turbocharger, engine designers are forced to reduce the compression ratio. This affects low-rpm efficiency, which brings drawbacks in terms of both mileage and drivability - turbo lag.

Various technical solutions for a variable compression ratio have been proposed for about 100 years now, but these were deemed unfeasible. The idea is to have an engine that can operate at a compression ratio that’s inversely proportional with the boost pressure.

This is where Porsche’s innovation steps in, as the Germans propose a solution that aims to be as simple and therefore as reliable as possible.

Porsche's design

As you can see in the patent drawing, it all involves an eccentric adjustment element, which is operated by hydraulic rods placed at both sides of the connecting rod. The eccentric element can rotate, thus slightly pulling the piston down and reducing the compression ratio.Porsche’s system features two positions rather than a range of actuation levels, in order to keep things feasible.

The application’s destination remains unknown for the moment

At first, this seems like the perfect application for a Porsche vehicle. After all, this is the brand whose cars use active stabilizer bars (PDCC) and ZF-supplied active rear steering.Then again the joint-development means the system could simply be a cash-delivering development that may show up in a vehicle outside the Porsche. This wouldn’t be the first time when the company lends its engineering expertise to another developer. For instance, the Opel Zafira MPV was developed with Porsche assistance.