Porsche looked at what others were doing with their all-electric units, studied every little aspect in detail, and then made the necessary decisions that led to the creation of the Taycan. So, what’s up with this vehicle having a two-speed gearbox and no one-pedal driving system? We focus on the latter a bit.

Today, contract manufacturing allows for a relatively easy EV-making process. Decide on the design, crop up a skateboard platform, find a battery and a motor supplier, pick the right components, establish a simple yet effective personalization process to have some margin opportunity, safe-test the car and obtain good results, create a marketing strategy based on the brand’s identity or transform the vehicle itself into one, and, voila, another all-electric automobile is ready to be launched into the world.

Of course, making a car from scratch takes time and requires many resources. But that’s not true for everyone. Some automakers managed to just rebadge a made-in-China EV and sell it as their own.

Not Porsche. The Stuttgart-based manufacturer was stubborn and determined enough to create a great first battery-electric vehicle (BEV). It was so bent on delivering a great unit that – to some degree – it even ignored what its parent company Volkswagen (VW) was doing or saying. That’s how the four-door clean sports car ended up having a different and arguably much better infotainment system, for example.

The entire effort put into developing a two-speed gearbox for a high-performance BEV and the fact that one-pedal driving was not a priority can’t be ignored as well. They represent an integral part of the same pioneering, courageous attitude.

Now, the Porsche Taycan is one of the manufacturer’s most successful products. It proved that Volkswagen Group was right to let engineers do their own thing, even though, at times, it may have seemed risky. Next up – the Macan EV. The proven powertrain will be installed in the successful crossover SUV. But until then, let’s look at something that at first was deemed to be a controversial thing to do – the absence of one-pedal driving.

Things drastically changed in 1998 when Porsche took everyone by surprise. The German brand announced its first-ever SUV, and four years later, the Cayenne was very, very real. Purists were mad at their cores. However, the Cayenne and later the Macan helped the automaker establish itself as one of the most sought-after contemporary manufacturers. That major success is one of the reasons why today we have the 911 Turbo S that’s hailed almost everywhere as the “near-perfect vehicle.” It’s no easy feat to achieve this level of marvelous engineering, and in all instances, it requires vast amounts of cash.

But Porsche was not satisfied with just the Cayenne, the Macan, and the Boxster. The world was changing again in the post-2010 era. Competitors that popularized a different kind of propulsion could once again put the German brand into an uncomfortable situation. So, this time, Porsche did not wait. After playing around with hybrid tech for a while (see the 918 Spyder), the carmaker told the world in 2015 that it was going to launch an all-electric model. Purists were once again on the fence about it, but they weren’t as vocal as when the Cayenne was announced.

Based on the Mission E concept, the Taycan started introducing itself to the world in late 2019. By 2020, the EV was present in virtually every market. Today, there are three body types available which amount to 14 variations. Last year, the brand sold 34,801 units, even though the cheapest Taycan has a starting price of $86,700 (excluding tax) in the U.S. and €93,522 ($101,726, including tax) in Europe. Some other market players offer BEVs with similar or better mi/kWh consumption for less money. But…

Porsche learned something valuable from building extremely powerful and limited-edition cars over the years – listen to the customer from time to time. That’s why some of its buyers’ feedback were incorporated into what the Taycan is today. And that’s something to praise, considering other automakers out there trying to educate the buyer into liking something new.

So, here it is – the Taycan without one-pedal driving or, better said, without the one-pedal driving system other automakers accustomed us to.

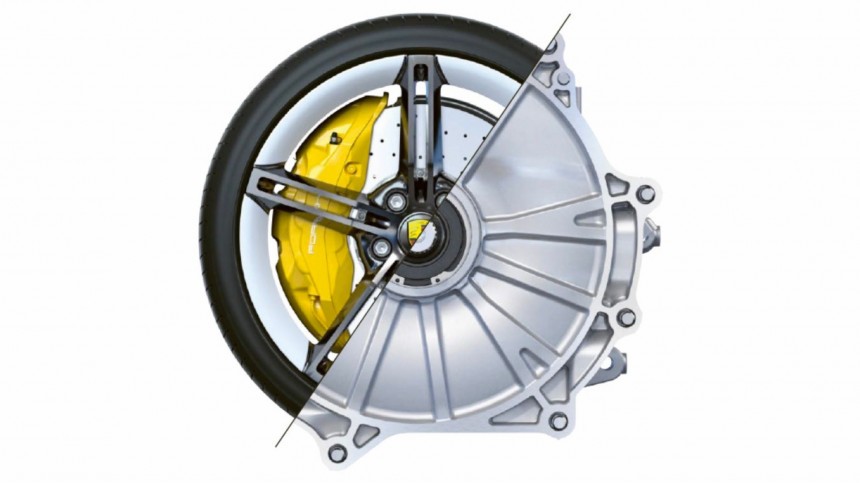

As presented in the latest edition of the Porsche Engineering Magazine, EVs come with two main challenges for chassis developers – weight and dynamics. These two factors tell engineers that the car they’re working on will need big hydraulic brakes to ensure proper stopping power.

But not the Taycan. The Performance Battery Plus may consist of a big 396-cell 93.4-kWh (nominal) pack, but that doesn’t mean it needs huge and heavy brakes. The electric motors can switch to recuperation mode, and they contribute to stopping the vehicle. But there’s a very important difference to be noted here.

Whereas other BEVs may have a one-pedal driving system that’s either tiered, activatable, or both and will immediately come into play as the driver lifts the foot off the throttle pedal, in the Taycan, things work differently. The energy recuperation system joins the party only when the person sitting behind the wheel presses the brake pedal.

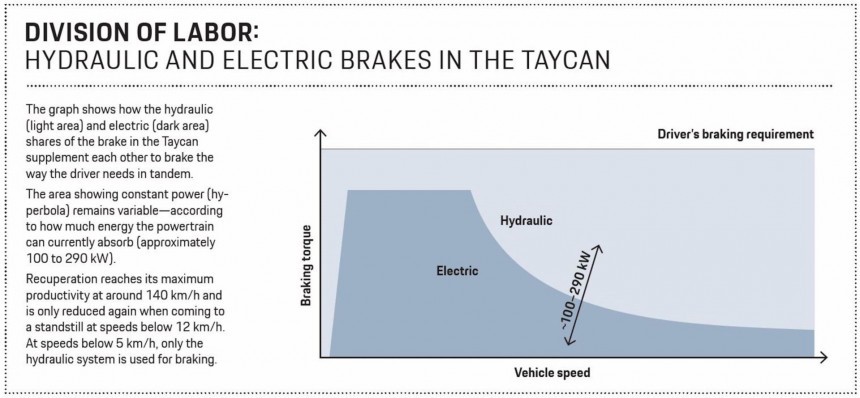

Porsche concluded that friction is needed only when the speed of the car is either too low (under 5kph/3mph), too high, or in emergencies when the driver mashes the brake. On a track day, decelerating from high speeds for two seconds can add enough juice to the battery to comfortably drive around for approximately 2,300 feet (700 meters).

The automaker believes that allowing the vehicle to coast when the driver does not intend to brake is the best outcome in this situation. And this posed some challenges.

Moreover, transitioning from hydraulic braking to electric motor stopping power can feel like an unwanted jostle most of the time. On top of this, braking power is distributed unevenly in vehicles. The front does most of the work, while the rear only gets to participate with one-third in stopping the car.

Porsche wanted to fix this. So, it developed algorithms for the Taycan that monitor the hydraulic braking system constantly. This way, the motors can effectively mirror what the friction brakes are doing. The weird outcome is that even though the rear electric motor is larger and could provide more braking power than the front motor, it still has to be limited to that third mentioned previously.

But this issue is not a barrier for Porsche. It provides the opportunity to fine-tune how braking force is distributed between the axles. The automaker wasn’t satisfied with the status quo and continued researching further.

In the end, it decided to make use of two algorithms – one that looks at the driving data and suggests a certain path for braking force to be distributed between the front and rear axles, while the second selects the best distribution possible and makes the decision. Mind you, this happens hundreds or even thousands of times per second.

While being a very technical solution, the ultimate result is that brake pads won’t wear faster, the hydraulic and electric motor braking won’t jolt the driver and the passengers, and decelerating will almost always translate into more range added back into the energy storage unit. Plus, one-pedal driving isn’t eliminated but upgraded!

The best thing about it, however, is that the upcoming Euro 7 pollution standard will measure brake wear. Porsche will most likely excel at this chapter since it does not use much material to make them, nor do the brakes need to be changed often.

Finally, this also opens the braking system domain for further enhancement or personalization. Engineers from various development departments can now work together to improve how parts of the vehicle interact. The practice was that braking experts don’t have to be kept in the loop – until now.

Of course, making a car from scratch takes time and requires many resources. But that’s not true for everyone. Some automakers managed to just rebadge a made-in-China EV and sell it as their own.

Not Porsche. The Stuttgart-based manufacturer was stubborn and determined enough to create a great first battery-electric vehicle (BEV). It was so bent on delivering a great unit that – to some degree – it even ignored what its parent company Volkswagen (VW) was doing or saying. That’s how the four-door clean sports car ended up having a different and arguably much better infotainment system, for example.

The entire effort put into developing a two-speed gearbox for a high-performance BEV and the fact that one-pedal driving was not a priority can’t be ignored as well. They represent an integral part of the same pioneering, courageous attitude.

In search of balance

Porsche was on the brink of bankruptcy in the early 1990s. But it saved itself from disappearing by innovating. Taking some inspiration from the legendary fun-to-drive and cheap-to-buy Miata, the automaker searched within its previous model lineup and found the 550 Roadster. In 1993, the famous Boxster appeared. It favored the appearance of the “poor man’s 911” saying, but it was so good that Porsche decided to continue improving it over the years.Things drastically changed in 1998 when Porsche took everyone by surprise. The German brand announced its first-ever SUV, and four years later, the Cayenne was very, very real. Purists were mad at their cores. However, the Cayenne and later the Macan helped the automaker establish itself as one of the most sought-after contemporary manufacturers. That major success is one of the reasons why today we have the 911 Turbo S that’s hailed almost everywhere as the “near-perfect vehicle.” It’s no easy feat to achieve this level of marvelous engineering, and in all instances, it requires vast amounts of cash.

But Porsche was not satisfied with just the Cayenne, the Macan, and the Boxster. The world was changing again in the post-2010 era. Competitors that popularized a different kind of propulsion could once again put the German brand into an uncomfortable situation. So, this time, Porsche did not wait. After playing around with hybrid tech for a while (see the 918 Spyder), the carmaker told the world in 2015 that it was going to launch an all-electric model. Purists were once again on the fence about it, but they weren’t as vocal as when the Cayenne was announced.

The best thing about EVs isn’t total electrification

It’s the innovation. That’s one of the reasons why Porsche already has a facelift in the works for the popular high-performance sedan, which might join the upcoming Macan EV. However, the German automaker’s stance on creating a better product than its competitors isn’t based on giving it a larger battery or turning the car into a weirdly shaped blob.Porsche learned something valuable from building extremely powerful and limited-edition cars over the years – listen to the customer from time to time. That’s why some of its buyers’ feedback were incorporated into what the Taycan is today. And that’s something to praise, considering other automakers out there trying to educate the buyer into liking something new.

So, here it is – the Taycan without one-pedal driving or, better said, without the one-pedal driving system other automakers accustomed us to.

As presented in the latest edition of the Porsche Engineering Magazine, EVs come with two main challenges for chassis developers – weight and dynamics. These two factors tell engineers that the car they’re working on will need big hydraulic brakes to ensure proper stopping power.

Whereas other BEVs may have a one-pedal driving system that’s either tiered, activatable, or both and will immediately come into play as the driver lifts the foot off the throttle pedal, in the Taycan, things work differently. The energy recuperation system joins the party only when the person sitting behind the wheel presses the brake pedal.

Porsche concluded that friction is needed only when the speed of the car is either too low (under 5kph/3mph), too high, or in emergencies when the driver mashes the brake. On a track day, decelerating from high speeds for two seconds can add enough juice to the battery to comfortably drive around for approximately 2,300 feet (700 meters).

The automaker believes that allowing the vehicle to coast when the driver does not intend to brake is the best outcome in this situation. And this posed some challenges.

Fixing “the blend”

While hydraulic braking power provides a certain amount of torque depending on weather conditions and how much pressure is applied, electric motors do the recuperation bit differently. The assemblies always deliver the same braking torque.Porsche wanted to fix this. So, it developed algorithms for the Taycan that monitor the hydraulic braking system constantly. This way, the motors can effectively mirror what the friction brakes are doing. The weird outcome is that even though the rear electric motor is larger and could provide more braking power than the front motor, it still has to be limited to that third mentioned previously.

But this issue is not a barrier for Porsche. It provides the opportunity to fine-tune how braking force is distributed between the axles. The automaker wasn’t satisfied with the status quo and continued researching further.

In the end, it decided to make use of two algorithms – one that looks at the driving data and suggests a certain path for braking force to be distributed between the front and rear axles, while the second selects the best distribution possible and makes the decision. Mind you, this happens hundreds or even thousands of times per second.

While being a very technical solution, the ultimate result is that brake pads won’t wear faster, the hydraulic and electric motor braking won’t jolt the driver and the passengers, and decelerating will almost always translate into more range added back into the energy storage unit. Plus, one-pedal driving isn’t eliminated but upgraded!

The best thing about it, however, is that the upcoming Euro 7 pollution standard will measure brake wear. Porsche will most likely excel at this chapter since it does not use much material to make them, nor do the brakes need to be changed often.

Finally, this also opens the braking system domain for further enhancement or personalization. Engineers from various development departments can now work together to improve how parts of the vehicle interact. The practice was that braking experts don’t have to be kept in the loop – until now.