Some of you are probably wondering how do Formula One cars, which reach speeds in excess of 200 mph (321 km/h), manage to brake so effectively at the end of a long straight. The high temperatures reached by the brake discs are enormous – sometimes exceeding 1000 degrees Celsius – so how do they manage to build those things that are able to sustain hundreds of brakes per race?

In order to see how a regular brake system works, you're very welcomed to visit our How Brakes Work article in the Guide section. Having said that, let's now focus on Formula One brakes, as they work on almost the same principle as in road cars, only they are made of different materials and undergo important changes in order to function at incredibly high temperatures.

First of all, the most important thing about an F1 braking system is that it is based on brake discs. During the course of their implementation in the Great Circle, the brake discs have been built out of steel, but time proved that carbon-made brake discs are certainly the safer and most effective way to go.

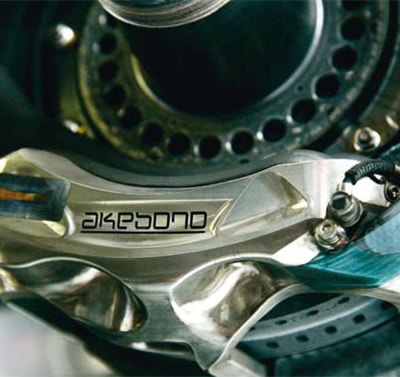

With both brake disc and caliper being made out of carbon fibre, it is ensured that the brakes will last at temperatures exceeding 1000 degrees Celsius. A Formula One brake disc is 28mm in thickness and 278mm in diameter, and is made out of the best possible carbon fibre there is on the market. In fact, the construction of such a brake disc can take a manufacturer no less than half-of-year.

The building process of the carbon fibers used for brake discs & calipers is as followed: one takes the regular PAN (white polyacrylo nitrile) fibres and pre-oxidizes them via a heating process. However, this is only the first part of the forming process, as the outcome of this maiden stage is later carbonized. Following the carbonization, the resulted material has to spend days up to weeks into high-temperature ovens (simulating the temperatures during the race, meaning somewhere around 1000 degrees Celsius), while combined with a hydrocarbon-rich gas. This way, the carbon fibre layers inside the oven will merge perfectly in order to create one fine piece of brake disc.

The final stage of the process is cutting the resulted material into the form of a brake disc, depending on the system used by each team in particular. F1 teams might also opt for different manufacturing companies, with Hitco, Brembo and Carbon Industries being on top of the preference list.

Now that we've got this covered, lets have a look at how the system really works. As compared to road cars, Formula One machineries have their braking system divided into front braking and rear braking, as ruled by the International Automobile Federation. The reason for that bifurcation of the braking system is related to safety issues, meaning should one of the system fail to work properly, the next one can be activated in order to slow the car down.

In addition to that function, the separation of the front & rear system allows the drivers to make use of brakes differently during the race. While most of the braking happens in the front end of the car, wet races (for example) require more efficient braking at the rear of the car. Also, being able to switch braking on front/rear also helps the drivers to preserve the tires against intense wear.

Two brake master cylinders from which brake fluid is pumped into the calipers' cylinders of both front and rear brake systems is located inside the suspension, in order to maximize the space within the car's chassis. When the driver pushes the brakes, the aforementioned fluid is inserted into the caliper's cylinders and leads to the contraction of the carbon brake block (located on the brake discs).

What's interesting about F1 braking is that the system is not activated at the exact time the driver pushes the brakes. In fact, for the first hundreds of a second – it may sound a very short period of time but, in F1 terms, it's translated into a considerable amount of time – the car behaves as if the brakes were not activated at all. The reason why that happens is that the process by which the brake discs and calipers come together needs to reach the best operating temperature – around 600 degrees Celcius. The braking temperatures grow 100 degrees Celsius every tenth of a second until half of second, as showed by f1technical.net.

After half of second had passed, the temperatures exceed 1000 degrees Celsius, causing the car to brake instantly. Which is actually the downside of the whole thing, as the deceleration is quite brutal on the drivers. Just to make an idea of it, know that a driver undergoes a horizontal force close to 5.4G when braking, as an F1 car can decelerate from 200 mph to a complete halt in only 4 seconds.

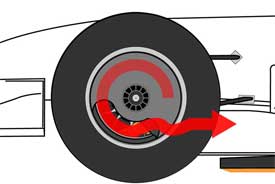

The second important part of a braking system for F1 machineries is the cooling system. We have to admit, no matter the material of which a the disc brake is made of, it cannot withstand the high temperatures described above without constant cooling. Formula One teams have used several solutions to improve cooling for the brakes, with the most important feature being the air ducts.

Air ducts are those little inlets created by the F1 mechanics in order to direct airflow towards the caliper and inside of the brake disc (located inside the wheel). In order to improve the airflow coming from outside the wheel, most teams have proceeded to fitting their rims with static wheel fairings. While also improving airflow around the car – as an aerodynamic effect – the aforementioned feature also directs air straight into the brakes, while also securing an improved brake exhaust airflow. The implementation of grooved brake discs was also aimed at keeping the brakes up to working temperatures.

In order to see how a regular brake system works, you're very welcomed to visit our How Brakes Work article in the Guide section. Having said that, let's now focus on Formula One brakes, as they work on almost the same principle as in road cars, only they are made of different materials and undergo important changes in order to function at incredibly high temperatures.

First of all, the most important thing about an F1 braking system is that it is based on brake discs. During the course of their implementation in the Great Circle, the brake discs have been built out of steel, but time proved that carbon-made brake discs are certainly the safer and most effective way to go.

With both brake disc and caliper being made out of carbon fibre, it is ensured that the brakes will last at temperatures exceeding 1000 degrees Celsius. A Formula One brake disc is 28mm in thickness and 278mm in diameter, and is made out of the best possible carbon fibre there is on the market. In fact, the construction of such a brake disc can take a manufacturer no less than half-of-year.

The building process of the carbon fibers used for brake discs & calipers is as followed: one takes the regular PAN (white polyacrylo nitrile) fibres and pre-oxidizes them via a heating process. However, this is only the first part of the forming process, as the outcome of this maiden stage is later carbonized. Following the carbonization, the resulted material has to spend days up to weeks into high-temperature ovens (simulating the temperatures during the race, meaning somewhere around 1000 degrees Celsius), while combined with a hydrocarbon-rich gas. This way, the carbon fibre layers inside the oven will merge perfectly in order to create one fine piece of brake disc.

The final stage of the process is cutting the resulted material into the form of a brake disc, depending on the system used by each team in particular. F1 teams might also opt for different manufacturing companies, with Hitco, Brembo and Carbon Industries being on top of the preference list.

Now that we've got this covered, lets have a look at how the system really works. As compared to road cars, Formula One machineries have their braking system divided into front braking and rear braking, as ruled by the International Automobile Federation. The reason for that bifurcation of the braking system is related to safety issues, meaning should one of the system fail to work properly, the next one can be activated in order to slow the car down.

In addition to that function, the separation of the front & rear system allows the drivers to make use of brakes differently during the race. While most of the braking happens in the front end of the car, wet races (for example) require more efficient braking at the rear of the car. Also, being able to switch braking on front/rear also helps the drivers to preserve the tires against intense wear.

Two brake master cylinders from which brake fluid is pumped into the calipers' cylinders of both front and rear brake systems is located inside the suspension, in order to maximize the space within the car's chassis. When the driver pushes the brakes, the aforementioned fluid is inserted into the caliper's cylinders and leads to the contraction of the carbon brake block (located on the brake discs).

What's interesting about F1 braking is that the system is not activated at the exact time the driver pushes the brakes. In fact, for the first hundreds of a second – it may sound a very short period of time but, in F1 terms, it's translated into a considerable amount of time – the car behaves as if the brakes were not activated at all. The reason why that happens is that the process by which the brake discs and calipers come together needs to reach the best operating temperature – around 600 degrees Celcius. The braking temperatures grow 100 degrees Celsius every tenth of a second until half of second, as showed by f1technical.net.

After half of second had passed, the temperatures exceed 1000 degrees Celsius, causing the car to brake instantly. Which is actually the downside of the whole thing, as the deceleration is quite brutal on the drivers. Just to make an idea of it, know that a driver undergoes a horizontal force close to 5.4G when braking, as an F1 car can decelerate from 200 mph to a complete halt in only 4 seconds.

The second important part of a braking system for F1 machineries is the cooling system. We have to admit, no matter the material of which a the disc brake is made of, it cannot withstand the high temperatures described above without constant cooling. Formula One teams have used several solutions to improve cooling for the brakes, with the most important feature being the air ducts.

Air ducts are those little inlets created by the F1 mechanics in order to direct airflow towards the caliper and inside of the brake disc (located inside the wheel). In order to improve the airflow coming from outside the wheel, most teams have proceeded to fitting their rims with static wheel fairings. While also improving airflow around the car – as an aerodynamic effect – the aforementioned feature also directs air straight into the brakes, while also securing an improved brake exhaust airflow. The implementation of grooved brake discs was also aimed at keeping the brakes up to working temperatures.