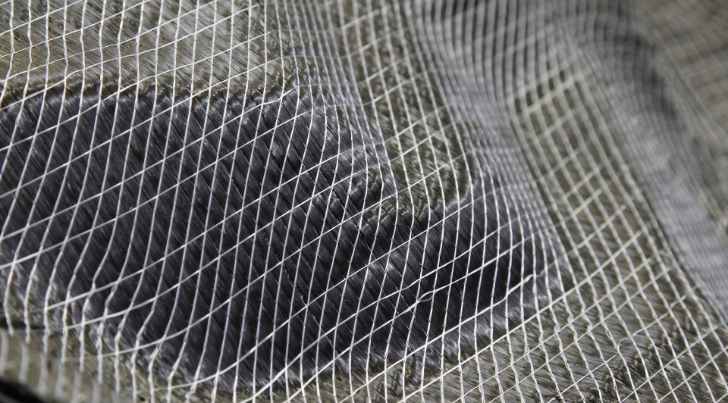

The first EV from BMW and the first production car to use CFRP to a high extent, the i3, is a success. The over 10,000 orders the Germans recorded in the last few weeks speak loud enough.

The thing is, there’s also a problem with this high-demand. The Moses Lake plant that makes the carbon fibre for all the components of the i3 has to work double time now, as Bimmetoday reports.

It seems like BMW and its partner in making the lightweight material, SGL Group, have to step up their game and start making a lot more CF to make sure everyone receives their i3 in time.

Another problem that might arise from this is the energy used in the process. Up until now BMW claimed that for the production of the EV they used a lot of renewable energy sources and, at some plants, that was the only energy used.

Since the production has to be doubled, will their windmills and hydroelectric power be enough? We certainly hope so, otherwise the ISO certificate the i3 received a while back might not be valid for too long.

It seems like BMW and its partner in making the lightweight material, SGL Group, have to step up their game and start making a lot more CF to make sure everyone receives their i3 in time.

Another problem that might arise from this is the energy used in the process. Up until now BMW claimed that for the production of the EV they used a lot of renewable energy sources and, at some plants, that was the only energy used.

Since the production has to be doubled, will their windmills and hydroelectric power be enough? We certainly hope so, otherwise the ISO certificate the i3 received a while back might not be valid for too long.