Ford is cooperating with the United Space Alliance (USA) to make better use of virtual reality applications. The automaker uses simulation software developed by video game developers and movie animators in order to pre-test its future car’s driving characteristics.

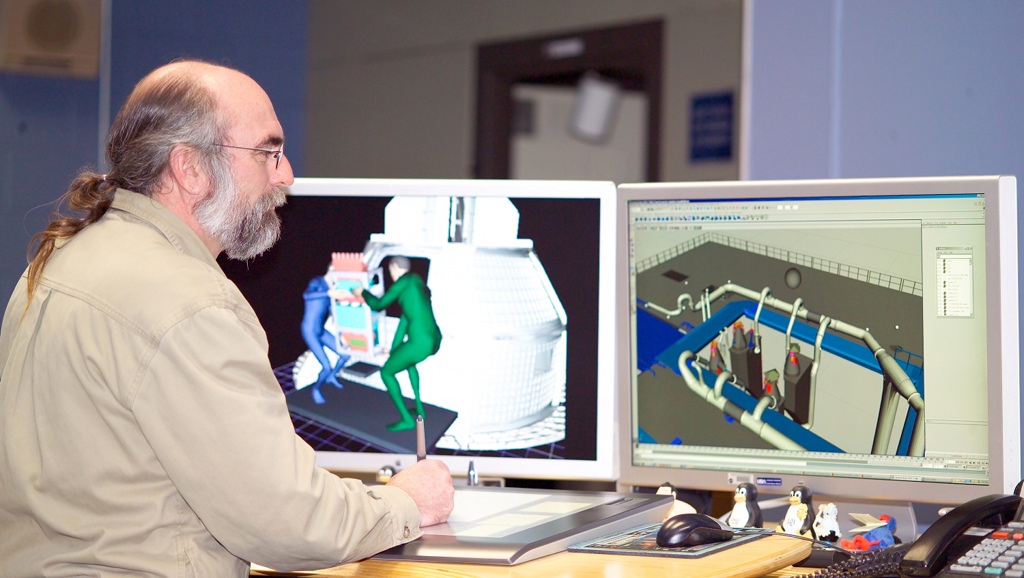

This is the task of the company’s Virtual Evaluation lab (iVE). The company’s engineers gather data from the tests performed here and use it to improve visibility, quality and comfort of the vehicles, thus reducing costs related to prototype building.

One example of a vehicle which has been enhanced at iVE is the Lincoln MKS. The lab simulations helped develop the interior’s ergonomics and offered engineers the possibility to test multiple configurations.

“In this virtual environment, we can evaluate early vehicle designs against a backdrop of virtual conditions and literally experience a vehicle from someone else’s vantage point before it is built, helping us to create a car, truck or crossover that provides the perfect environment for the driver and its occupants,” said Elizabeth Baron, Ford’s Virtual Reality and Advanced Visualization Technical Specialist.

Baron has created connections with other industries for using virtual reality. Through the implementation of virtual tools such as animation software, Ford engineers have managed to reduce a vehicle’s development time by eight to fourteen months, as compared to the average period of time needed for a car’s development five years ago.

Engineers working for USA, the prime space shuttle contractor, are relying on the same technology at the Kennedy Space Center to produce future space vehicles safer and more efficiently. Current applications include the tracking and characterization of launch debris during ascent.

Ford and USA are sharing their knowledge for a mutual benefit. Ford engineers have helped USA to specify software enhancements to human simulation software and motion tracking technology with the aim of simulating spacecraft repairs. In exchange, USA engineers have trained Ford engineers in order to enhance the immersive virtual experience by improving response time, allowing for a smoother and more realistic environment.

“Helping our designers build cars that are a better fit for drivers and passengers is a thrill and teaming up and sharing ideas with USA for the benefit of our space program is a whole other level of cool. We’ve learned a great deal from USA about how to make our virtual lab even more life-like for engineers and designers so our new vehicles look and feel just right inside,” Baron said.

The automotive industry has always adopted solutions from its aeronautical big sister. This is how the carbon fiber has made its way to cars, for example. Now, the automotive segment is mature and the two are working together, for drivers and astronauts' benefit. Think about this the next time when you push a button in your car.

This is the task of the company’s Virtual Evaluation lab (iVE). The company’s engineers gather data from the tests performed here and use it to improve visibility, quality and comfort of the vehicles, thus reducing costs related to prototype building.

One example of a vehicle which has been enhanced at iVE is the Lincoln MKS. The lab simulations helped develop the interior’s ergonomics and offered engineers the possibility to test multiple configurations.

“In this virtual environment, we can evaluate early vehicle designs against a backdrop of virtual conditions and literally experience a vehicle from someone else’s vantage point before it is built, helping us to create a car, truck or crossover that provides the perfect environment for the driver and its occupants,” said Elizabeth Baron, Ford’s Virtual Reality and Advanced Visualization Technical Specialist.

Baron has created connections with other industries for using virtual reality. Through the implementation of virtual tools such as animation software, Ford engineers have managed to reduce a vehicle’s development time by eight to fourteen months, as compared to the average period of time needed for a car’s development five years ago.

Engineers working for USA, the prime space shuttle contractor, are relying on the same technology at the Kennedy Space Center to produce future space vehicles safer and more efficiently. Current applications include the tracking and characterization of launch debris during ascent.

Ford and USA are sharing their knowledge for a mutual benefit. Ford engineers have helped USA to specify software enhancements to human simulation software and motion tracking technology with the aim of simulating spacecraft repairs. In exchange, USA engineers have trained Ford engineers in order to enhance the immersive virtual experience by improving response time, allowing for a smoother and more realistic environment.

“Helping our designers build cars that are a better fit for drivers and passengers is a thrill and teaming up and sharing ideas with USA for the benefit of our space program is a whole other level of cool. We’ve learned a great deal from USA about how to make our virtual lab even more life-like for engineers and designers so our new vehicles look and feel just right inside,” Baron said.

The automotive industry has always adopted solutions from its aeronautical big sister. This is how the carbon fiber has made its way to cars, for example. Now, the automotive segment is mature and the two are working together, for drivers and astronauts' benefit. Think about this the next time when you push a button in your car.