Whether it’s SAF (sustainable aviation fuel) or green hydrogen, the alternatives to conventional jet fuel are still not easily available and affordable, and the future isn’t looking any brighter either. Switching to clean energy alternatives is expensive. But the solution could come from aircraft design, more specifically the computer code for flow simulation.

The high costs of alternative fuels could be compensated through greater fuel efficiency, meaning the aircraft of the future should be designed to make the most of these fuels.

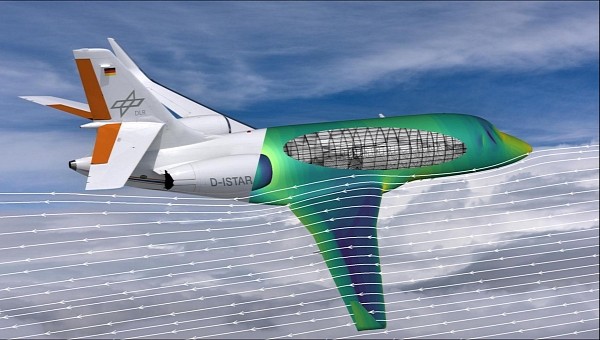

This is the core belief of a large team of experts who are working on something called CFD - Computational fluid dynamics. This type of computer-aided simulation could help aircraft with the best fuel efficiency possible, simply through the properties of their design.

This advanced design will be able to achieve two things – maximize lift, and minimize drag. This way, aircraft could burn less fuel even at high speed.

The way to get there is through state-of-the-art computer code. And the team that’s working on it joins specialists from three aerospace giants: Airbus, DLR (the German Aerospace Center) and the ONERA (Office National d’Etudes et de Recherches Aerospatiales) aerospace laboratory in France.

Although they’ve been collaborating for many decades, the three partners joined forces for this particular project back in 2017. Prior to that, each of them had been developing their own computer code. By working together, they can accelerate the development of a new generation CFD code.

At this point, the code is ready for extensive testing, which is why the three partners have confirmed a new phase of the project at the end of 2023. Through this, the CFD will be extended for several Airbus applications, such as the ZeroE, EcoPulse, and OpenFan.

Back in 2020, Airbus had unveiled three aircraft concepts with different propulsion systems, but those were designed to run on liquid hydrogen. The boldest one envisioned a large airliner that could carry 200 passengers over 2,000 nautical miles (2,300 miles/3,700 km) with no emissions.

Two years later, Airbus presented the latest development in the Zeroe project. This was a dedicated storage tank that could maintain hydrogen at extreme temperatures. According to the manufacturer, it only took one year to develop this cryogenic tank prototype, which is the first of its kind for Airbus.

There’s still a long road ahead for the ZeroE project – a fully-functional cryogenic tank will be ready to be integrated onto an Airbus A380, and tested, within the next five years.

While working on its separate projects, such as the ZeroE, Airbus also offers support to the team that’s developing the CFD code, by providing access to its extreme-scale computational systems, which are considered to be some of the best ones in the world.

This is the core belief of a large team of experts who are working on something called CFD - Computational fluid dynamics. This type of computer-aided simulation could help aircraft with the best fuel efficiency possible, simply through the properties of their design.

This advanced design will be able to achieve two things – maximize lift, and minimize drag. This way, aircraft could burn less fuel even at high speed.

The way to get there is through state-of-the-art computer code. And the team that’s working on it joins specialists from three aerospace giants: Airbus, DLR (the German Aerospace Center) and the ONERA (Office National d’Etudes et de Recherches Aerospatiales) aerospace laboratory in France.

Although they’ve been collaborating for many decades, the three partners joined forces for this particular project back in 2017. Prior to that, each of them had been developing their own computer code. By working together, they can accelerate the development of a new generation CFD code.

At this point, the code is ready for extensive testing, which is why the three partners have confirmed a new phase of the project at the end of 2023. Through this, the CFD will be extended for several Airbus applications, such as the ZeroE, EcoPulse, and OpenFan.

Back in 2020, Airbus had unveiled three aircraft concepts with different propulsion systems, but those were designed to run on liquid hydrogen. The boldest one envisioned a large airliner that could carry 200 passengers over 2,000 nautical miles (2,300 miles/3,700 km) with no emissions.

Two years later, Airbus presented the latest development in the Zeroe project. This was a dedicated storage tank that could maintain hydrogen at extreme temperatures. According to the manufacturer, it only took one year to develop this cryogenic tank prototype, which is the first of its kind for Airbus.

There’s still a long road ahead for the ZeroE project – a fully-functional cryogenic tank will be ready to be integrated onto an Airbus A380, and tested, within the next five years.

While working on its separate projects, such as the ZeroE, Airbus also offers support to the team that’s developing the CFD code, by providing access to its extreme-scale computational systems, which are considered to be some of the best ones in the world.