Because of the high price of jet fuel, but also as a means to help the environment a bit, most airlines and airplane makers out there are trying to find ways to reduce fuel consumption. Most of them are looking into making plane engines capable of running on sustainable aviation fuel (SAF), others are hoping for hybridization, and a few are even pondering going all electric. But not Japan Airlines.

Like many others in this business, the country’s largest airline had been actively trying to cut down on its fuel consumption. One of the ways it does that is not by trying out some new engine tech, but by coming up with a crazy idea to make minor alterations to a plane’s body shape. An idea inspired by the skin of sharks.

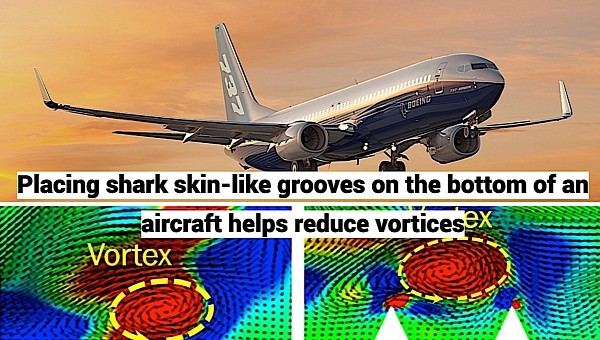

You see, the skin of these creatures is riddled with grooves that help water glide on their bodies without offering that much resistance. It’s a riblet-type design that has been researched in the aviation industry for a while, but it was only recently that Japan Airlines announced a world first.

Given how research into this matter has been going on for a while, there are cases when airplanes fly with riblets attached as decals and films. Such a design helps move away the vortices that form near the surface area of an airplane, resulting in decreased skin friction. Consequently, less friction means less fuel used to overcome air resistance.

But the Japanese carrier now claims to be the first to have applied riblets directly over the aircraft’s external paint. What this method does is increase the durability of the riblets, but also reduce the weight they add to the plane.

It’s unclear at this point how much fuel can be saved if the shark skin-inspired riblets are applied where they’re needed in this manner. Japan Airlines, together with the country’s space agency, JAXA, are presently flight testing the riblets on two Boeing 737-800 aircraft, mounted on the bottom of the planes’ main fuselages.

One of the planes is fitted with riblets made by a company called O-Well Corporation, and tests on this one have already reached 1,500 flight hours. The second one has Nikon-sourced riblets, and it’s at half the number of flight hours. The elements used on both of them, says JAXA, “have been confirmed to have sufficient durability.”

We’re not told if and when this method of applying riblets directly over the aircraft’s external paint will become the norm, but tests will continue in the coming months.

It’s also unclear how much fuel these things will help save, but just to give you an idea of how things are now, consider the CFM56 high-bypass turbofan engine that powers the Boeing 737-800 needs up to 850 gallons (3,200 liters) of fuel per hour to carry 162 passengers and cargo to their destination.

You see, the skin of these creatures is riddled with grooves that help water glide on their bodies without offering that much resistance. It’s a riblet-type design that has been researched in the aviation industry for a while, but it was only recently that Japan Airlines announced a world first.

Given how research into this matter has been going on for a while, there are cases when airplanes fly with riblets attached as decals and films. Such a design helps move away the vortices that form near the surface area of an airplane, resulting in decreased skin friction. Consequently, less friction means less fuel used to overcome air resistance.

But the Japanese carrier now claims to be the first to have applied riblets directly over the aircraft’s external paint. What this method does is increase the durability of the riblets, but also reduce the weight they add to the plane.

One of the planes is fitted with riblets made by a company called O-Well Corporation, and tests on this one have already reached 1,500 flight hours. The second one has Nikon-sourced riblets, and it’s at half the number of flight hours. The elements used on both of them, says JAXA, “have been confirmed to have sufficient durability.”

We’re not told if and when this method of applying riblets directly over the aircraft’s external paint will become the norm, but tests will continue in the coming months.

It’s also unclear how much fuel these things will help save, but just to give you an idea of how things are now, consider the CFM56 high-bypass turbofan engine that powers the Boeing 737-800 needs up to 850 gallons (3,200 liters) of fuel per hour to carry 162 passengers and cargo to their destination.