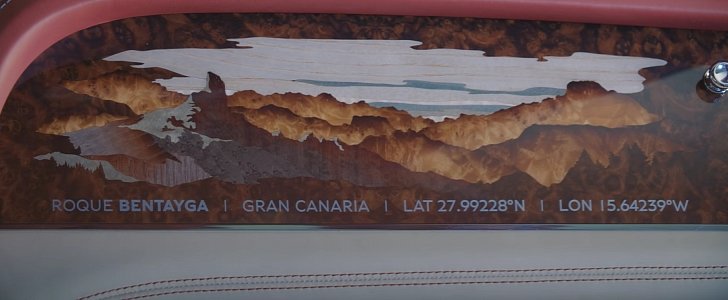

Bentley named its first SUV, the Bentayga, after the Roque Bentayga, located in the Gran Canaria Islands. The luxury carmaker's Mulliner division decided to pay an homage to the famous rock formation, so it developed a select veneer for the British SUV. However, when it was first presented, it was not explained to us how Bentley managed to create it.

In the meantime, the British brand from Crewe published a video on its YouTube account. In the video, some of its employees explain how these intricate designs are achieved.

Instead of a fancy printer and exquisite finishes that mimic wood, Bentley does this veneer by hand, in an unmentioned timeframe.

The company describes the period as a “time-honoured process,” and just mention “hours of manual skill,” and sophisticated artistry. This video shows another side of the work, which involves 32 layers of different wood.

Imagine working with 32 pieces of paper in various colors and you would have a bad time when doing some Origami.

Furthermore, these 32 sheets come from six species of trees, so they react differently, and must be combined to achieve a variety of hues. Bentley does not mention this, but it must take a level of patience and talent that 's hard to find these days.

The team of artisans from Mulliner do implement modern technology in their work. However, they only do this to achieve effects that would take too much time by hand, or could not have optimal results without them. All the inlay is done by hand, just like the lacquering process.

With these painstaking tasks, it is easy to understand why Mulliner’s intervention costs so much on a car. Just imagine being the person that has to pick the types of tree that are used for the veneers, and then make a selection from the best of them.

Another selection is required, and then the artisan looks for elements to use in inlays. The grain of the wood must be perfect, and its pattern must be admirable. So this beautiful detail requires many tens of hours of work, from conception to accomplishment.

Instead of a fancy printer and exquisite finishes that mimic wood, Bentley does this veneer by hand, in an unmentioned timeframe.

The company describes the period as a “time-honoured process,” and just mention “hours of manual skill,” and sophisticated artistry. This video shows another side of the work, which involves 32 layers of different wood.

Imagine working with 32 pieces of paper in various colors and you would have a bad time when doing some Origami.

Furthermore, these 32 sheets come from six species of trees, so they react differently, and must be combined to achieve a variety of hues. Bentley does not mention this, but it must take a level of patience and talent that 's hard to find these days.

The team of artisans from Mulliner do implement modern technology in their work. However, they only do this to achieve effects that would take too much time by hand, or could not have optimal results without them. All the inlay is done by hand, just like the lacquering process.

With these painstaking tasks, it is easy to understand why Mulliner’s intervention costs so much on a car. Just imagine being the person that has to pick the types of tree that are used for the veneers, and then make a selection from the best of them.

Another selection is required, and then the artisan looks for elements to use in inlays. The grain of the wood must be perfect, and its pattern must be admirable. So this beautiful detail requires many tens of hours of work, from conception to accomplishment.