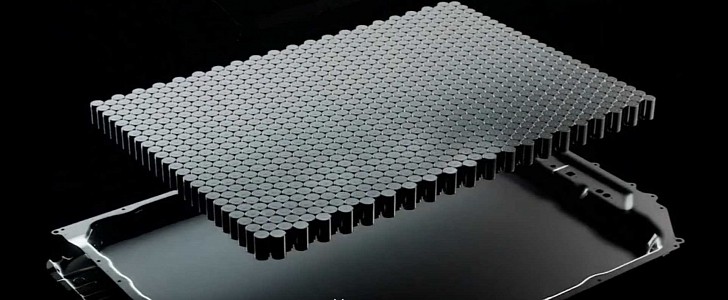

Tesla introduced us to their 4680 cells at Battery Day in September 2020, but one year and a half later there is no sign that the new cells are production-ready. Tesla’s Kato Road facility, where the new cells are developed, still functions as an R&D center and a leaked document shows the production figures are too low to count.

Tesla tried to persuade us their new 4680 cells are a game-changer once they’re rolling out “anytime soon.” Recent information points to the mass production starting no sooner than 2023, showing that cracking the new cells takes more than just packing them in bigger rolls. Tesla battery R&D center in Kato Road is busy increasing the output, but with yields still low this risks affecting the quality of cells.

A document leaked on the Tesla Motors Club forum shows the production yields and levels for January 22 at the Kato Road facility and these are not looking very good. Although the picture shared by user Oliver’s TMX is low resolution, he offers more insight, as the info comes from a relative who works at the facility.

The document shows that 14 machines were in operation that day and 13 of them were producing “good” cells, with yields above 90%. One machine is the exception, producing only a limited number of good cells. According to Oliver’s relative, this machine was used that day to train employees from Giga Texas, which explains the high rate of rejects.

“Green represents good batteries and red is for rejects. As you can see, on that day they had 14 machines running and produced 92% good batteries, including the 82% bad batteries from Machine 212 which I believe was being used that day to train folks from Texas who will be producing them there in the future,” he wrote.

On the right side of the document, we see the most common causes of defects. “Flap folding in – Cathode” leads with 1.4%, followed closely by “Single Wind Cut Position Recovery – Cathode” at 1.2%. Even with Machine 212 ruining it, the overall yield for that day was at 92%, which may sound impressive but this still means 8% of the cells are thrown away.

The production figure also shows around 6,250 cells were manufactured that day. Estimates indicate around 600 of them would be needed for a complete structural battery for the Model Y assembled in Texas. This should allow building some 10 Model Ys daily, which is far from the targeted Texas production. Tesla would need to ramp up 4680 cells production 100-fold just to feed Gigafactory Texas.

As the 4680 cells will get into mass production, Giga Texas will be making them on site, just as Giga Berlin will have to do. Tesla’s battery partners like Panasonic, LG, and Samsung are also working to bring their 4680 line to production. Until then, we found out that Tesla started using the 2170 cells inside the structural batteries.

A document leaked on the Tesla Motors Club forum shows the production yields and levels for January 22 at the Kato Road facility and these are not looking very good. Although the picture shared by user Oliver’s TMX is low resolution, he offers more insight, as the info comes from a relative who works at the facility.

The document shows that 14 machines were in operation that day and 13 of them were producing “good” cells, with yields above 90%. One machine is the exception, producing only a limited number of good cells. According to Oliver’s relative, this machine was used that day to train employees from Giga Texas, which explains the high rate of rejects.

“Green represents good batteries and red is for rejects. As you can see, on that day they had 14 machines running and produced 92% good batteries, including the 82% bad batteries from Machine 212 which I believe was being used that day to train folks from Texas who will be producing them there in the future,” he wrote.

On the right side of the document, we see the most common causes of defects. “Flap folding in – Cathode” leads with 1.4%, followed closely by “Single Wind Cut Position Recovery – Cathode” at 1.2%. Even with Machine 212 ruining it, the overall yield for that day was at 92%, which may sound impressive but this still means 8% of the cells are thrown away.

The production figure also shows around 6,250 cells were manufactured that day. Estimates indicate around 600 of them would be needed for a complete structural battery for the Model Y assembled in Texas. This should allow building some 10 Model Ys daily, which is far from the targeted Texas production. Tesla would need to ramp up 4680 cells production 100-fold just to feed Gigafactory Texas.

As the 4680 cells will get into mass production, Giga Texas will be making them on site, just as Giga Berlin will have to do. Tesla’s battery partners like Panasonic, LG, and Samsung are also working to bring their 4680 line to production. Until then, we found out that Tesla started using the 2170 cells inside the structural batteries.