For a while now 3D printing has been making its way into automotive production processes. Still a long way of becoming norm, the additive manufacturing (AM) technology as it’s also called is already making its mark.

For the moment, 3D printed parts are limited to secondary hardware, like body parts, but soon we’ll probably see even pistons made this way, just like Porsche plans on doing. But even with the current limited use, the results are both encouraging and remarkable.

Take Chevrolet, for instance, because it is the bowtie carmaker who decided to share a bit of data of how such parts perform in the race cars it fields in American competitions, such as IndyCar and NASCAR.

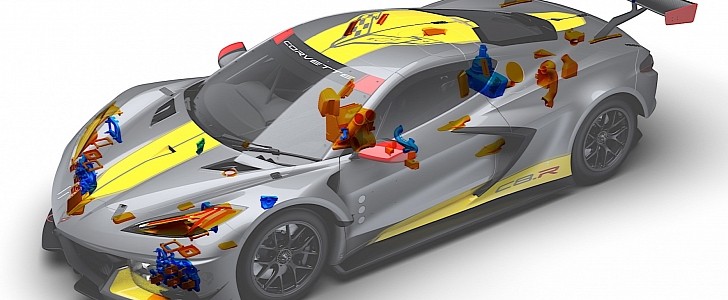

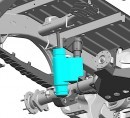

The stunning Corvette C8.R for instance, has 75 3D-printed parts fitted on it, including the oil tank, tank inlet and cap, air conditioning driver cooling box, integrated hydration system, power steering pump bracket and headlight assemblies. Since the car made its debut at the Rolex 24 at Daytona in January, the two examples of the car raced for 8,000 miles (12,800 km) without reporting issues with these components.

In IndyCar, the exhaust system used by the racers are 3D-printed, and since it is fitted on a lot more cars, in managed to amass some 60,000 miles (96,500) to its name since June without problems.

And there’s the Silverado that competed in the Best in the Desert Method Race Wheels Laughlin Desert Classic sporting a rear damper shield made this way with carbon-fiber reinforced plastic; or the NASCAR Camaro ZL1 1LE that features 3D made parts not only on its body, but also the gear cooling duct.

In all, says Chevy, such hardware was raced for over 80,000 miles (128,700 km) combined this year, becoming a major pro for the expanded use of AM.

“By utilizing 3D-printed parts, Chevrolet Motorsports is demonstrating the many benefits of additive manufacturing, including manufacturing efficiencies, mass reduction, parts consolidation, creativity and cost savings,” said in a statement Audley Brown, GM director, Materials Engineering, Additive Design and Manufacturing.

“3D-printed parts can offer equal strength and durability to cast or milled components, which is critical for product development and design.”

Take Chevrolet, for instance, because it is the bowtie carmaker who decided to share a bit of data of how such parts perform in the race cars it fields in American competitions, such as IndyCar and NASCAR.

The stunning Corvette C8.R for instance, has 75 3D-printed parts fitted on it, including the oil tank, tank inlet and cap, air conditioning driver cooling box, integrated hydration system, power steering pump bracket and headlight assemblies. Since the car made its debut at the Rolex 24 at Daytona in January, the two examples of the car raced for 8,000 miles (12,800 km) without reporting issues with these components.

In IndyCar, the exhaust system used by the racers are 3D-printed, and since it is fitted on a lot more cars, in managed to amass some 60,000 miles (96,500) to its name since June without problems.

And there’s the Silverado that competed in the Best in the Desert Method Race Wheels Laughlin Desert Classic sporting a rear damper shield made this way with carbon-fiber reinforced plastic; or the NASCAR Camaro ZL1 1LE that features 3D made parts not only on its body, but also the gear cooling duct.

In all, says Chevy, such hardware was raced for over 80,000 miles (128,700 km) combined this year, becoming a major pro for the expanded use of AM.

“By utilizing 3D-printed parts, Chevrolet Motorsports is demonstrating the many benefits of additive manufacturing, including manufacturing efficiencies, mass reduction, parts consolidation, creativity and cost savings,” said in a statement Audley Brown, GM director, Materials Engineering, Additive Design and Manufacturing.

“3D-printed parts can offer equal strength and durability to cast or milled components, which is critical for product development and design.”