Science is amazing. It gave us amongst every single item that surrounds us, cars, engineering, the HEMI V8 engine, and 3D printers. All the more reasons for one YouTuber to test physics with a very ingenious build that involves all of the above.

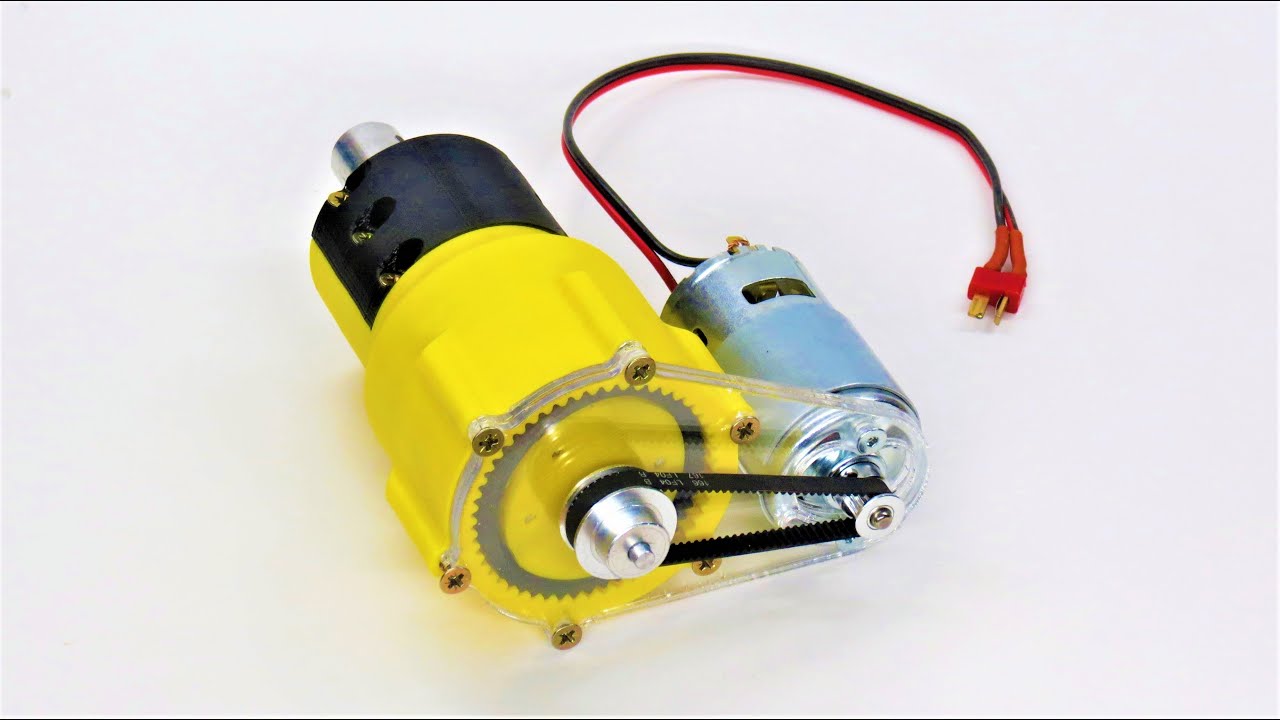

A 3D-printed, 12 VDC-operated mini winch with a strain wave gearbox is strong enough to pull a 2016 Dodge Charger R/T with a 392 HEMI idling under the hood. Please don't take my word for it; click play on the video and see for yourselves.

The ingenious YouTuber Brian Brocken built a fully functional plastic and metal winch. Nothing that special about this project so far. However, the operating principle is interesting – the details are explained on his hackaday.io profile page (together with all his other projects).

Brian is a professional gearhead (all his other projects documented on YouTube stand as solid proof of his appeal to gears), and testing his latest brainchild required appropriate means. Brian built the strain wave winch because the mechanical efficiency of the traditional reduction gearboxes wasn't good enough.

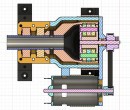

This flexible gear design eliminates the unnecessary intermediate cogs between the input and the output shafts. (The video thoroughly explains the mechanics behind this type of engineering). But here comes the fun part of the story – the mandatory proof of concept.

Brian chose the gearhead-most approach – he would real-life test his plastic winch with a Dodge Charger. After building a prototype to check the functionality of his design, the full-scale winch parts came out of the 3D printer. With improvements in material quality and hoist architecture, Brian set the stage for the bench test.

Take that literally - the engineer screwed the pulley assembly onto his workbench and proceeded to dyno measurements. With phase one testing completed, it was time for the actual trial. Enter the Dodge Charger. And not just any Charger, but the 392 HEMI - Brian carefully got the badge on video - he "borrowed for a limited time."

All in the interest of science, of course (but there is more than one way a Mopar can serve science). The 392 (6.4-liter) HEMI V8 muscle idled meekly in the garage while the winch, powered by its 12 V tiny electric motor, put tension on the rope.

So, there it is: a 4,400 lb Dodge (two tons), 475 lb-ft (644 Nm) muscle car casually towed by a crank with 2.95 lb-ft (4Nm) maximum tested torque and a final ratio of approximately 54:1 (54.0855:1, for science's sake). Science is fantastic, I know! Hats off to Brian Brocken and his work.

However, he could hardly have pulled off (PUN intended, yes) his stunt without the help of the blue Charger. (I guess the Mopar-loving society can add "Cogs and Gears Test Mule" on the list of "What to use a 392 HEMI Charger for").

Since we are autoevolution, here are the gearhead details about the unsung hero of this science project, the 2018 Dodge Charger R/T, 392 CID (6.4-liter) HEMI V8. The score of 0-60 mph (0-96 kph) is 4.2 seconds. Multiply this threefold, and the standing quarter-mile is covered (12.6 seconds) at 115 mph (185 kph). Keep flooring it to peak 175 mph (282 kph). And, in case things go awry and the car needs to be winched on a trailer, there is one ingenious YouTuber who can always lay a helping 3D printed hand.

The ingenious YouTuber Brian Brocken built a fully functional plastic and metal winch. Nothing that special about this project so far. However, the operating principle is interesting – the details are explained on his hackaday.io profile page (together with all his other projects).

Brian is a professional gearhead (all his other projects documented on YouTube stand as solid proof of his appeal to gears), and testing his latest brainchild required appropriate means. Brian built the strain wave winch because the mechanical efficiency of the traditional reduction gearboxes wasn't good enough.

This flexible gear design eliminates the unnecessary intermediate cogs between the input and the output shafts. (The video thoroughly explains the mechanics behind this type of engineering). But here comes the fun part of the story – the mandatory proof of concept.

Brian chose the gearhead-most approach – he would real-life test his plastic winch with a Dodge Charger. After building a prototype to check the functionality of his design, the full-scale winch parts came out of the 3D printer. With improvements in material quality and hoist architecture, Brian set the stage for the bench test.

Take that literally - the engineer screwed the pulley assembly onto his workbench and proceeded to dyno measurements. With phase one testing completed, it was time for the actual trial. Enter the Dodge Charger. And not just any Charger, but the 392 HEMI - Brian carefully got the badge on video - he "borrowed for a limited time."

All in the interest of science, of course (but there is more than one way a Mopar can serve science). The 392 (6.4-liter) HEMI V8 muscle idled meekly in the garage while the winch, powered by its 12 V tiny electric motor, put tension on the rope.

So, there it is: a 4,400 lb Dodge (two tons), 475 lb-ft (644 Nm) muscle car casually towed by a crank with 2.95 lb-ft (4Nm) maximum tested torque and a final ratio of approximately 54:1 (54.0855:1, for science's sake). Science is fantastic, I know! Hats off to Brian Brocken and his work.

However, he could hardly have pulled off (PUN intended, yes) his stunt without the help of the blue Charger. (I guess the Mopar-loving society can add "Cogs and Gears Test Mule" on the list of "What to use a 392 HEMI Charger for").

Since we are autoevolution, here are the gearhead details about the unsung hero of this science project, the 2018 Dodge Charger R/T, 392 CID (6.4-liter) HEMI V8. The score of 0-60 mph (0-96 kph) is 4.2 seconds. Multiply this threefold, and the standing quarter-mile is covered (12.6 seconds) at 115 mph (185 kph). Keep flooring it to peak 175 mph (282 kph). And, in case things go awry and the car needs to be winched on a trailer, there is one ingenious YouTuber who can always lay a helping 3D printed hand.