Even though the 2.5 has its hiccups, Nissan is much obliged to boast the engine features the mirror bore process of the GT-R. These powerplants couldn’t be more different, let alone the difference in pricing and character between the mid-size sedan and Godzilla.

Manufactured in Decherd, the Tennessee-built engine reduces friction while improving efficiency. The plant is capable of manufacturing in the ballpark of 1.4 million engines per year, including the PR25DD in the Altima. For the 2019 model year, Nissan also offers the KR20DDET, an all-aluminum engine with variable compression ratio.

"Advanced technology like the mirror bore process only makes sense for Nissan if we can offer it to as many customers as possible," commented Jay Boyte, director of engineering at Decherd Powertrain. "The end result is an innovative and efficient engine made with manufacturing technology usually not available at this volume or price point.”

What’s up with the mirror bore process? It all starts with spraying and polishing the cylinders. During the spraying phase, sparks fly while charged metal wire is blown, atomizing the material and coat inside of the cylinders. The coating is 200 microns thick, translating to 0.2 millimeters or twice the thickness of human hair.

The second stage involves a special drill containing bits of diamonds that were unfit for jewelry. Spinning at high speed inside the cylinder, the drill polishes the metal of the cylinder walls. Water is applied during this stage to keep the drill and cylinders cool while reducing friction.

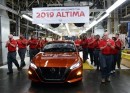

Decherd Powertrain is Nissan’s highest-volume engine plant in the U.S., assembling 1 million engines annually. Since it was opened in 1997, Nissan claims the total engine production at Decherd is “nearly 13 million.” Located 90 miles southeast of Nashville, the facility is the workplace of 1,700 people.

The mid-size sedan retails at $24,000 excluding destination in the United States, and Canada gets Intelligent AWD as standard. The VC-Turbo engine option, priced at $29,400, is FWD-only. Higher still, the range-topping Altima is the Edition ONE with the VC-Turbo at $35,750.

"Advanced technology like the mirror bore process only makes sense for Nissan if we can offer it to as many customers as possible," commented Jay Boyte, director of engineering at Decherd Powertrain. "The end result is an innovative and efficient engine made with manufacturing technology usually not available at this volume or price point.”

What’s up with the mirror bore process? It all starts with spraying and polishing the cylinders. During the spraying phase, sparks fly while charged metal wire is blown, atomizing the material and coat inside of the cylinders. The coating is 200 microns thick, translating to 0.2 millimeters or twice the thickness of human hair.

The second stage involves a special drill containing bits of diamonds that were unfit for jewelry. Spinning at high speed inside the cylinder, the drill polishes the metal of the cylinder walls. Water is applied during this stage to keep the drill and cylinders cool while reducing friction.

Decherd Powertrain is Nissan’s highest-volume engine plant in the U.S., assembling 1 million engines annually. Since it was opened in 1997, Nissan claims the total engine production at Decherd is “nearly 13 million.” Located 90 miles southeast of Nashville, the facility is the workplace of 1,700 people.

The mid-size sedan retails at $24,000 excluding destination in the United States, and Canada gets Intelligent AWD as standard. The VC-Turbo engine option, priced at $29,400, is FWD-only. Higher still, the range-topping Altima is the Edition ONE with the VC-Turbo at $35,750.