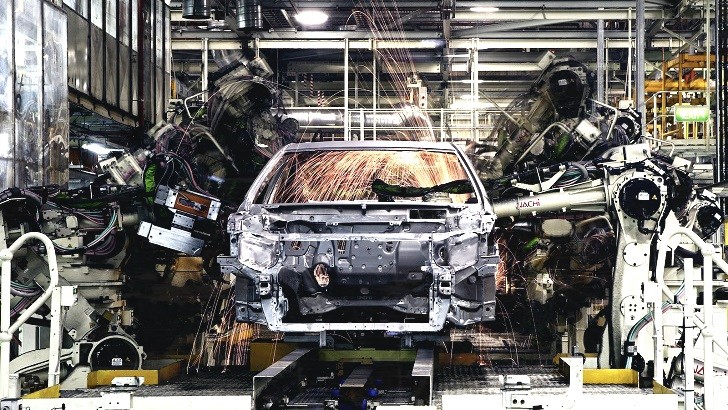

Toyota Motor Corporation is the top automaker when it comes to using robots for its vehicle production. This was a major factor which made it the top automaker with annual vehicle production surpassing its competitors.

Relying on robots to make your vehicles has advantages and disadvantages. Yes, its good for rapidly producing cars because robots are more accurate in what they do than humans, but there are things only humans can differentiate.

Just rushing to make a large number of cars will eventually lead to your decay as a renowned automaker. And here you can see what happened to Toyota a few years ago with the sticky accelerator pedal case. You need humans to assure each vehicle comes out as it should be, and the automaker is now bringing them back.

Toyota is now looking to bring back skilful technicians to improve production lines and manufacturing process. These craftsmen were used to be called 'gods' (Kami-sama) in the automaker's plants because of their increased skills.

“We need to become more solid and get back to basics, to sharpen our manual skills and further develop them. When I was a novice, experienced masters used to be called gods, and they could make anything,” veteran Mitsuru Kawai who is responsible of the program, told Bloomberg.

“We cannot simply depend on the machines that only repeat the same task over and over again. To be the master of the machine, you have to have the knowledge and the skills to teach the machine,” Kawai added.

And by bringing back the Kami-sama, Toyota is also confirming CEO Akio Toyoda's new strategy that won't concentrate that much on volumes, but more on its vehicles' quality and driving enjoyment.

Just rushing to make a large number of cars will eventually lead to your decay as a renowned automaker. And here you can see what happened to Toyota a few years ago with the sticky accelerator pedal case. You need humans to assure each vehicle comes out as it should be, and the automaker is now bringing them back.

Toyota is now looking to bring back skilful technicians to improve production lines and manufacturing process. These craftsmen were used to be called 'gods' (Kami-sama) in the automaker's plants because of their increased skills.

“We need to become more solid and get back to basics, to sharpen our manual skills and further develop them. When I was a novice, experienced masters used to be called gods, and they could make anything,” veteran Mitsuru Kawai who is responsible of the program, told Bloomberg.

“We cannot simply depend on the machines that only repeat the same task over and over again. To be the master of the machine, you have to have the knowledge and the skills to teach the machine,” Kawai added.

And by bringing back the Kami-sama, Toyota is also confirming CEO Akio Toyoda's new strategy that won't concentrate that much on volumes, but more on its vehicles' quality and driving enjoyment.